By reaping the benefits of new technologies, the machining world is constantly evolving to address new manufacturing challenges. Machine shops are facing global competition for faster production and tighter tolerances while also struggling to gain and retain reliable employees in a tight labor market. Current trends in the industry are aimed to address these issues. These advancements are being enabled through the use of advanced software and automation.

Learn The Ins and Outs of 5-Axis Machining

Through the implementation of new software powered by Artificial Intelligence (AI) technology, machine shops will be able to design and produce parts more quickly and at a higher quality. Advances in control, engineering, and interface software can also enable machine shops to produce parts faster with employees that will require less knowledge and training. Below are three examples of current trends in machining that will help shape the future of the industry.

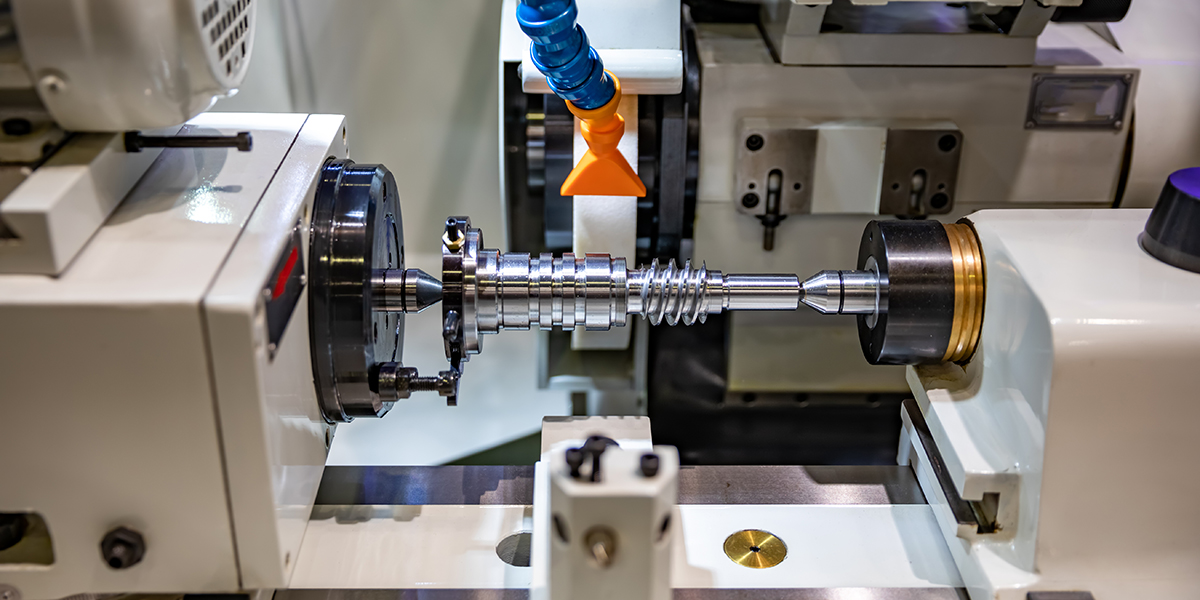

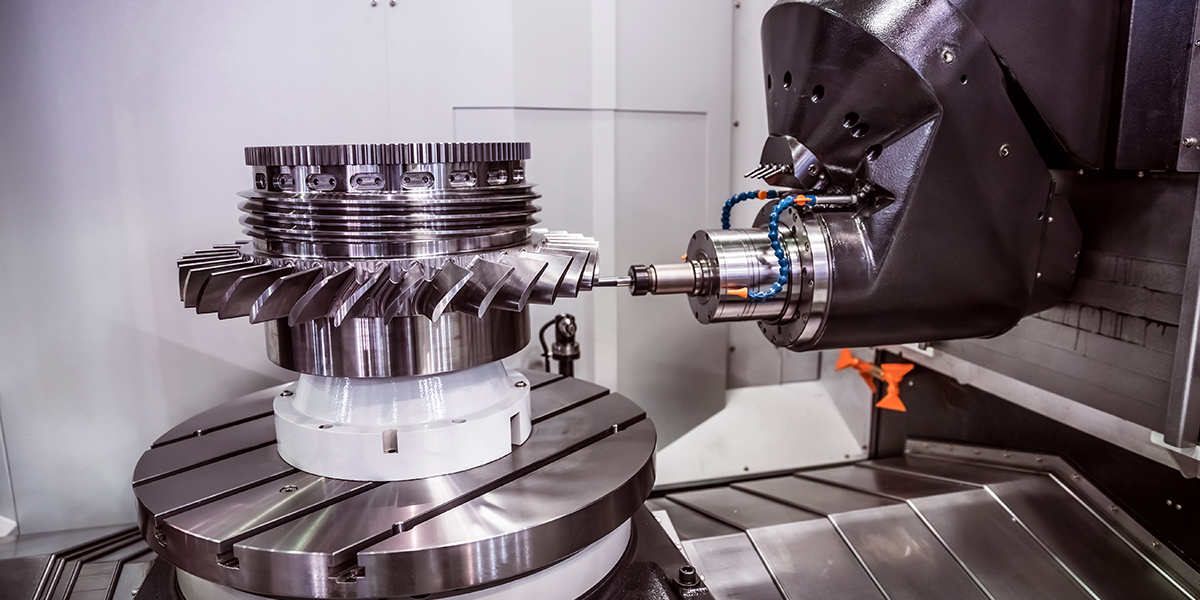

One trend helping to shape the machining industry is advancements in process automation. The rise of Computer Numerical Control (CNC) technology is allowing machine shops to produce high-quality products with better precision in a shorter period through increased automation. By incorporating machines such as automated loaders and robot arms to a process, a machine shop can increase its quality and production without having to hire or train new employees. This also allows employees to better monitor systems and perform maintenance more routinely and consistently.

A robotic gantry picks up parts and efficiently places them into the CNC machine to be machined.

Generative design is a current trend in machining that utilizes AI software and cloud technologies to help engineers create better solutions. This technology creates solutions for engineers based on their design problem’s parameters. Generative design software works by analyzing parameters such as materials, size, weight, strength, manufacturing methods, and cost constraints to create design solution options for a project based on cloud data. This is a quick way for engineers to consider many options faster throughout the design phase.

Software is also addressing the shortage of knowledgeable, trained employees by simplifying user interfaces. This may sound trivial, but with simpler custom interfaces less tech-savvy employees can be relied on to produce quality parts more quickly and with less training. These interfaces can be set to allow different employees access to different functions based on their need. In addition to user-friendly machine interfaces, machine shops are also utilizing Bluetooth and smart phone interface technology to allow for better monitoring of machines, processes, and quality quickly on the shop floor.

These are just a few examples of new technologies and software allowing shops to increase quality and production while simplifying the work for the end user. Capitalizing on current trends in machining will help shops compete in their ever-changing global industry.