If you’re new to the machining world and you find yourself intimidated by all the technical terms and machinist slang you’re suddenly asked to know, we certainly understand this stress. There’s a lot to know and if you need to make a purchase or a sale, then an error can be a costly one—both literally and theoretically. Being able to discuss machines or machining techniques is a valuable skill for anyone who works in the manufacturing sector or just wants to know more about it. So, without further ado, let’s talk about some machining terminology.

Check out our Guide to CNC Lathes

Let’s start with some of the acronyms.

CNC: Computer Numerical Control—a CNC machine is the automated control of machining tools by a computer. A CNC machine processes a piece of material such as metal to meet the specifications designed by a computer.

CMM: Coordinate Measuring Machine—a device that measures the geometry of physical objects, by sensing discrete points on the surface of the object using a probe. The probe may be mechanical, optical, laser, or white light.

CAD: Computer-Aided Design—a program that allows designers to digitally create parts that will then be programmed into and made on a CNC machine.

CAM: Computer-Aided Machining—a computer program that takes the CAD file and allows you to create paths for the cutting process on the CNC machine. The CAM directs the CNC machine where to go and how fast to move and spin for the desired outcome.

WCS: Work coordinate system—is what tells the CNC where a part is positioned or oriented within the machine using the orientation of the XYZ axis.

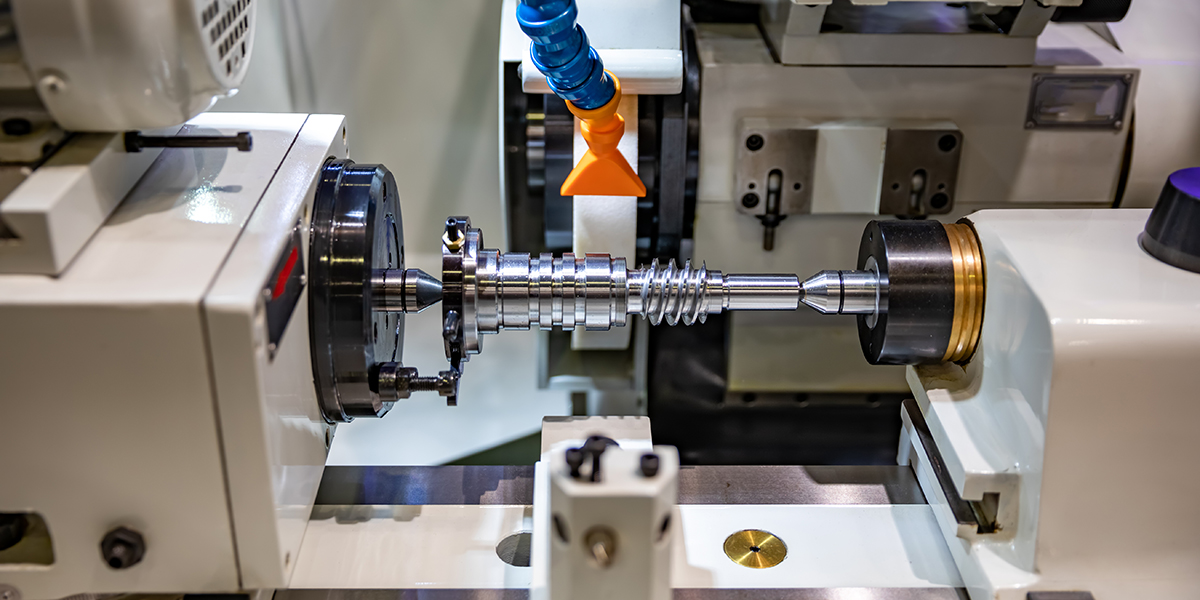

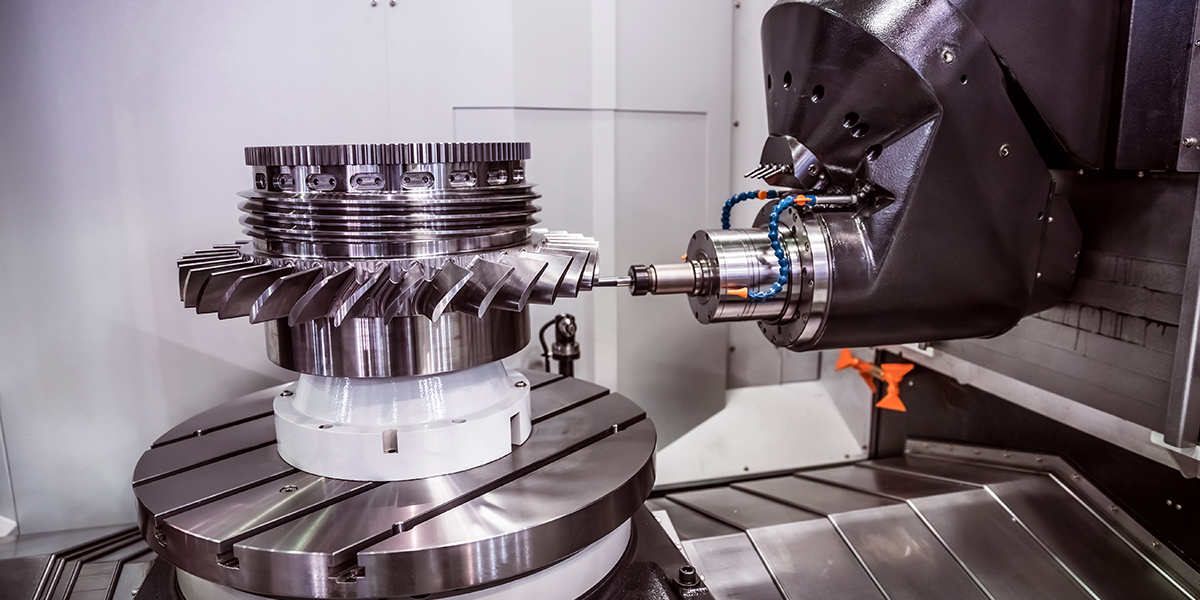

Cutting tools come in a wide variety of shapes and sizes to accommodate a variety of jobs.

Let’s now look at some other important terms to know:

Toolholding: the apparatus designed to hold cutting bits or tools. On a mill, for example, this is often the element that spins, but on a lathe, this is the element that is secured the workpiece to the table.

Cutting tool: A component that is used to remove stock from a work piece. Cutting tools can be made of tool steel, solid carbide, carbide inserts, cobalt, or ceramic. The edges of the tool are sharpened into specific geometries to accommodate cutting conditions.

Depth of Cut: Closely related to speed and feeds, depth of cut is how much material is going to be removed with each pass of the tool. This is another adjustment that can be made to improve surface finish and/or the life of the tool.

Thou: A machinist’s term for a unit of measurement equaling 0.001″ or a thousandth of an inch.

Tenth: Not to be mistaken for a tenth of an inch, a tenth is a unit of measurement equaling 0.0001″ or one ten-thousandths on an inch.

Facing: Machining stock down to a predetermined set height, usually using a larger tool than for other operations.

Coolant: A catch-all term for various cutting fluids or compounds used to increase tool life and improve surface finish on the material of the parts.

Chips: Small bits of waste material that fall away from the workpiece as it is being worked.

Cam: No, not CAM (see above) a cam is a device for converting regular rotary motion to reciprocating motion.

This is, of course, not a complete dictionary of machining terminology—more like a short glossary of some common and uncommon terms that fly around a machine shop the way chips do. And if you didn’t know what that meant before, you do now!