If you are searching for a machine shop to produce precision parts and bridge gaps in your supply chain, choosing the right partner is crucial. What every product owner, purchasing agent and manufacturing engineer is hoping to find is a machine shop that delivers parts within spec, on time, at a competitive price. Before outsourcing your manufacturing needs, take a moment to assess these three critical areas:

Equipment & Capabilities

Find a partner that stands out with a comprehensive array of modern machinery, including CNC machining, Swiss turning, and 5-axis milling. Make sure the shop is equipped to handle the most advanced and precise manufacturing demands. This requires a state-of-the-art facility that is optimized for maximum efficiency and also has ample room for assembly and storage. Make sure their team of machinists, operators and quality staff are experienced working in tight tolerances and delivering parts of the highest quality.

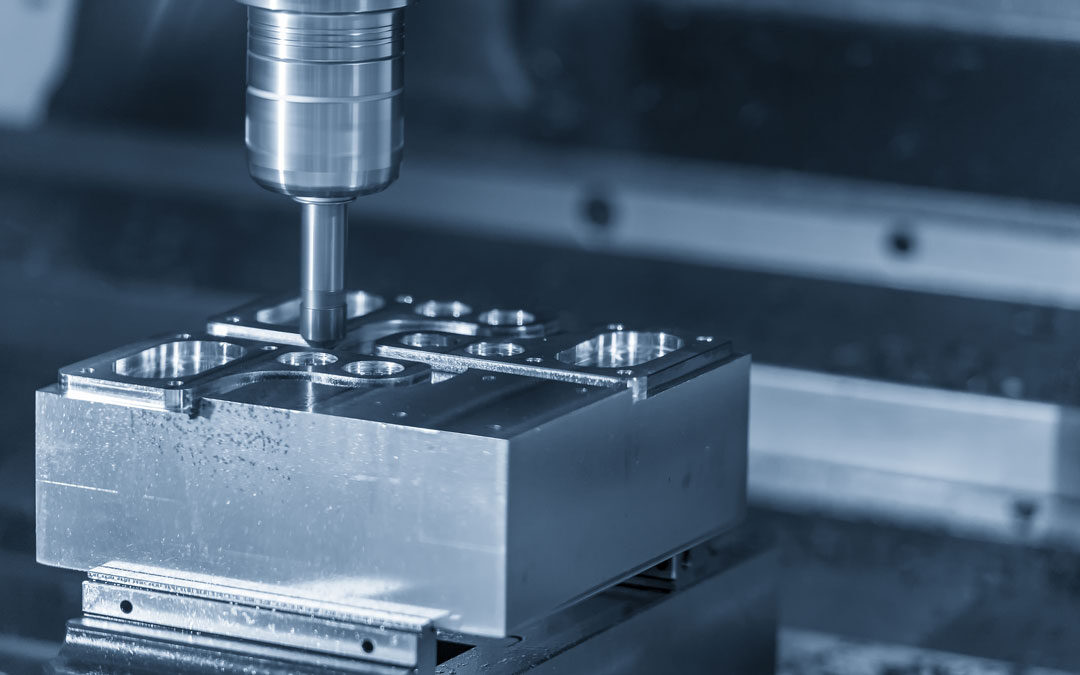

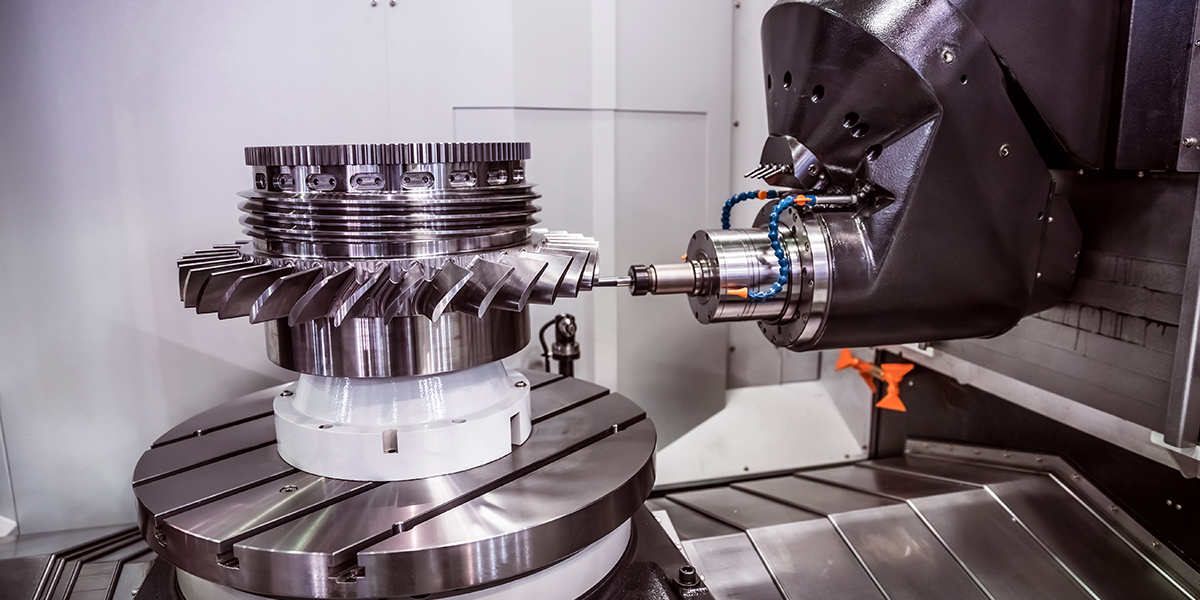

Milling

Advanced milling with multi-axis precision, consistent machine performance, and efficient CNC controls for rapid production and inspection.

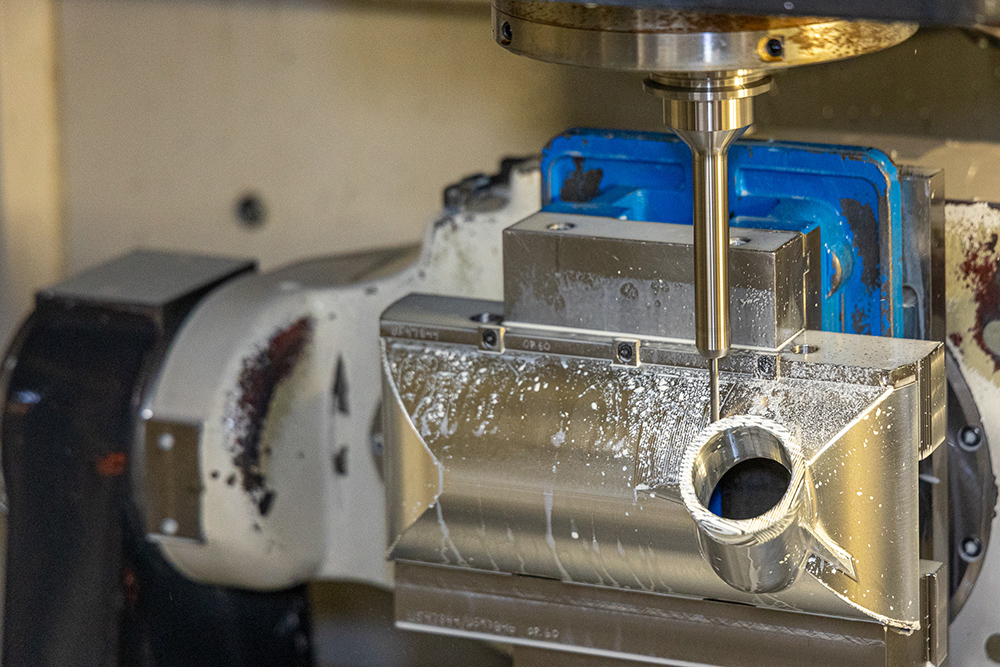

5-Axis

5-Axis milling enhances productivity and delivery of complex parts, reduces setup time and costs, and delivers higher accuracy and superior part quality.

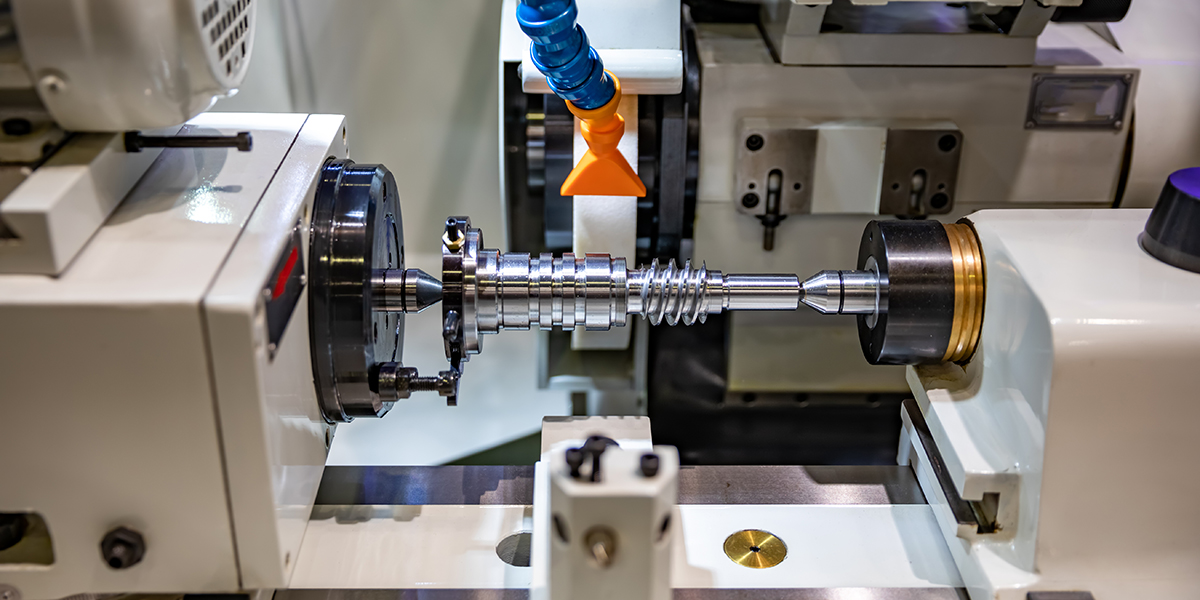

Turning

Turning integrates dual-spindle finishing, machining center capabilities, expanded Y-axis geometry machining, and bar feeding for streamlined, automated production.

Swiss CNC

Swiss CNC ensures superior accuracy and efficiency, offering high feed rates, a power-driven sub-spindle for reduced processing times, single-setup complex machining, and versatile tooling for various industry needs.

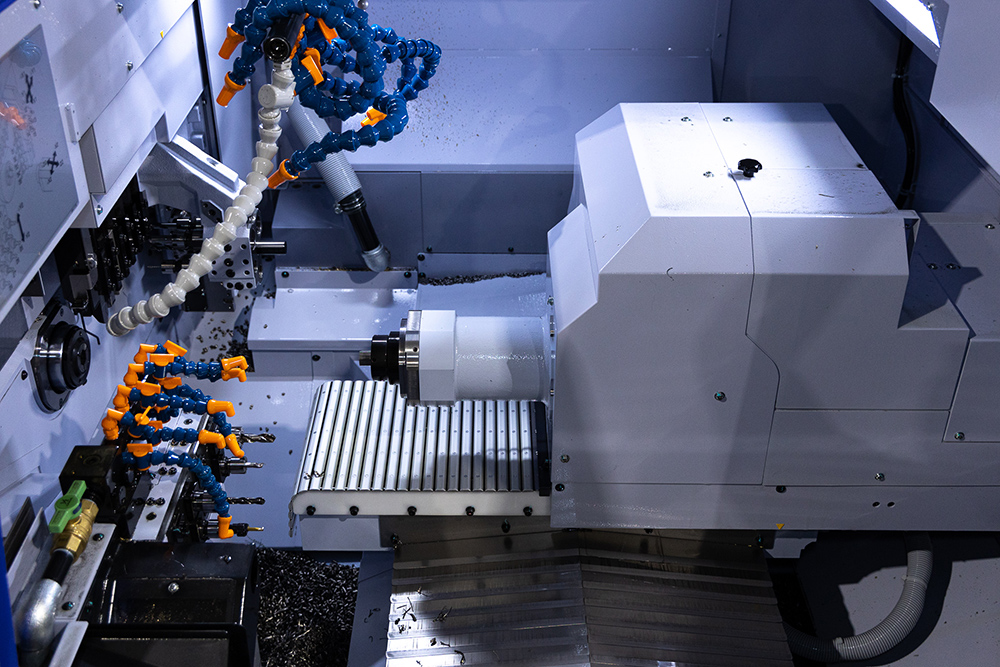

Automation

Automation includes bar feeders, gantry loaders, Palletech systems, and articulating robots for streamlined operations.

The type of part you need impacts the machine shop you choose to partner with.

Delivery & Reliability

Industry standards are and important part of modern manufacturing. AS9100D and ISO 9001:2015 certifications ensure that your machine shop has demonstrated the ability to provide products that meet the highest quality standards. These certifications also sow that your potential partner is dedicated to constantly improving efficiency, productivity, and customer satisfaction.

Communication & Partnership

Effective and transparent communication forms the backbone of our operations. You’re not jus looking for a parts supplier; you need a strategic partner. From product inception through delivery, find a machine shop that maintains open lines of communication and identifies ways to provide long-term value such as:

- Short and Long Production Runs: Flexibility to manage varied order sizes.

- Vendor Managed Inventory (VMI): Limited management effort required on your part.

- Dedicated Support: Whether 5 parts or 3000, every project receives the attention and engineering resources it requires.

Learn More About Our Technology & Services

Choosing a machine shop is more than just comparing prices and capabilities; it’s about ensuring a seamless and reliable partnership that can evolve with your needs. Winndeavor embodies this philosophy, striving to deliver not just parts, but peace of mind and continual support in your manufacturing efforts. Contact us today to get started with a top-quality machining partner.