For years modern manufacturing has highlighted the advantages of lean manufacturing and implementing lean principles into industrial production. While its principles of defining value, streamlining delivery, and pursuing improvement can help businesses, there is little explanation as to what are the advantages of lean manufacturing. How exactly does lean manufacturing improve production? Below, we’ll discuss the seven advantages of lean manufacturing and detail how each one creates improvement into an organization’s daily functions.

Streamline Inventory Management – Download Your Comprehensive VMI Checklist!

Waste Minimization

Arguably the most significant advantage of lean manufacturing comes from cutting waste from production. This waste comes not only from excess materials wasted during production, but also from production processes that overuse time, cost, energy, fuel, transportation, or inventory storage. Lean manufacturing prevents such an excess of wasted materials by removing unneeded functions within the company to improve productivity. In addition, this process reduces the costs within the operation. By removing wasteful operations from the process, organizations are able to free their time and space while improving profits.

Safer Environment

Lean manufacturing causes businesses to reduce their machine operations along with inventory. As a result, more space is opened up within the company, giving daily processes safety and organizational advantages to protect employees.

Cost reduction

One of the key advantages of lean manufacturing is reducing costs. By cutting wasteful steps from the production process, expenses are significantly cut to increase daily company profits. And in cutting wasteful expenses from production, an organization gains opportunities to invest their extra profits in expansion, employee training, or new production utilities beyond their current supply.

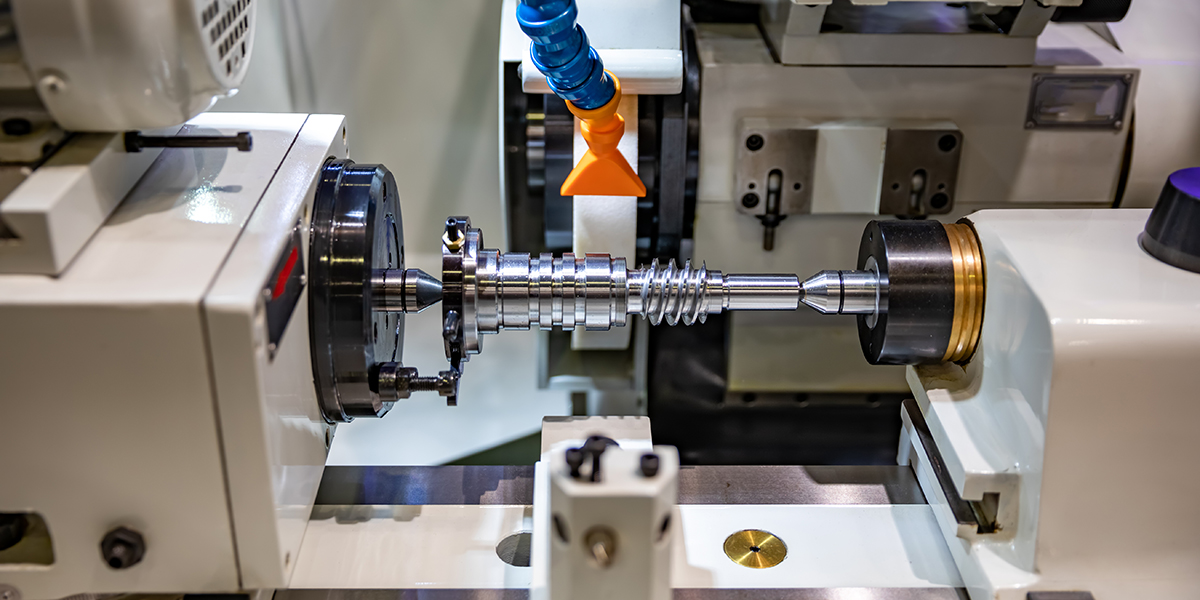

Streamlined process

Since lean manufacturing frees up extra space throughout production, this leaves room for more machinery within the company. As more machinery enhances the production process, businesses evidently gain an edge over competition by streamlining processes for faster delivery. Yet, production isn’t the only area streamlined; rather than appealing to all customers, another advantage to lean manufacturing is businesses can focus directly on loyal customers’ concerns. As a result, a stronger reputation is established with loyal clients, and thus streamlines a more reliable flow of revenue.

Lean manufacturing unifies different departments within a company.

Company & Employee Unity

Lean management is not limited to just a particular floor or department of the organization, but rather incorporated throughout every level of production. So, for an organization to benefit from the advantages of lean manufacturing, all lean principles must be input in each department to unify the business as a whole team. Through this process, employees develop a sense of belonging that fosters a better company culture as well as daily work performance.

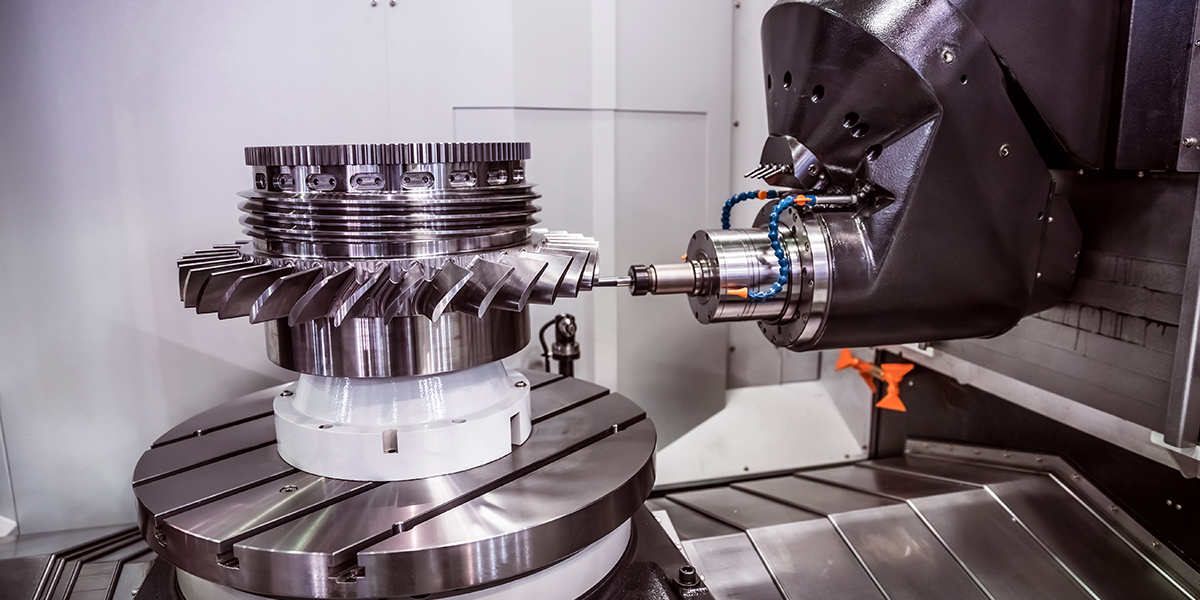

Higher Quality and Productivity

One of the best advantages of lean manufacturing is by removing excess steps and equipment, companies inevitably develop higher quality services. Once all major issues in inventory and production are resolved, businesses can prioritize their energy on market delivery and customer demand. Essentially, lean manufacturing clears away obstacles in an organization’s productive growth, allowing the business to adapt to production trends while staying relevant against competitors.

Improved Customer Relationships

Of all the advantages of lean manufacturing, the last results from all previous points working to enhance customer experiences with the company. Removing waste frees up staff work as well as production processes within the company, resulting in fewer inventory delays and more time availability to customers. Ultimately, lean manufacturing works in every department to improve quality and efficiency of products, thereby allotting more time to build loyalty and trust with clients.

The advantages of lean manufacturing work throughout a company’s system to increase productivity, quality, and overall satisfaction by employees and reliable clients. Aside from the benefits listed, though, manufacturers can create more opportunities and value for their businesses than previously thought. If you’re a lean manufacturer looking to outsource some of your part numbers or a company looking for a strategic partnership with a precision machine shop – we’re here to help. Contact us today!