In a competitive manufacturing environment, manufacturers need customizable, flexible solutions to meet their customers’ needs. And when that’s the case, there’s nothing quite like a short-run or small-batch production.

This method of production is a leaner, more nimble approach to production. It is designed to meet specific needs for any given project, without the overhead of traditional long-run production. The result? A more responsive process.

So, let’s talk about the key reasons why and times where small-batch production may be a better way to produce your parts.

Understanding Short Run and Small Batch Production

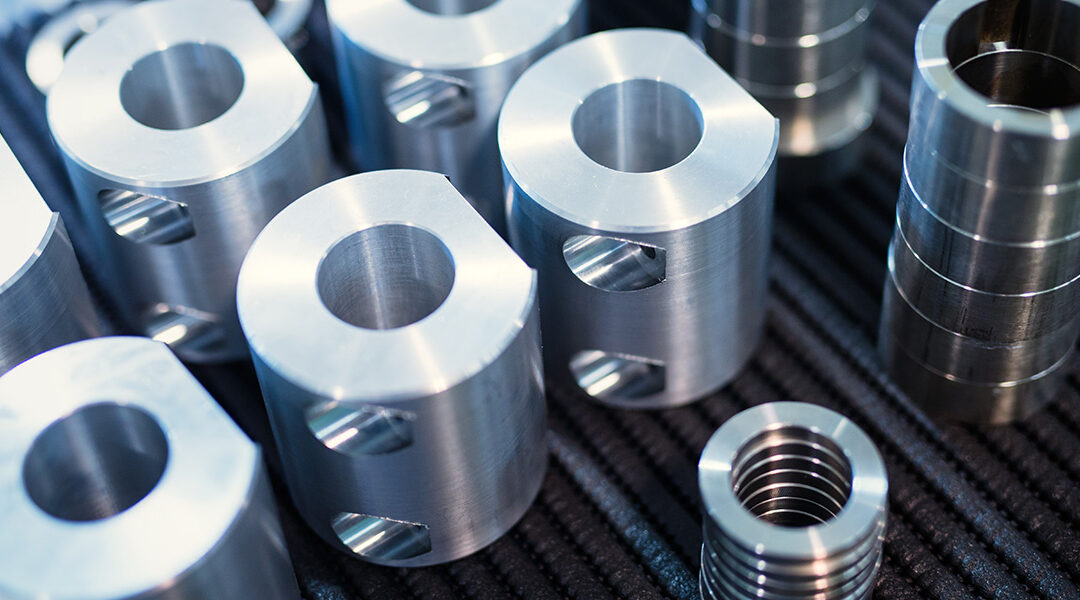

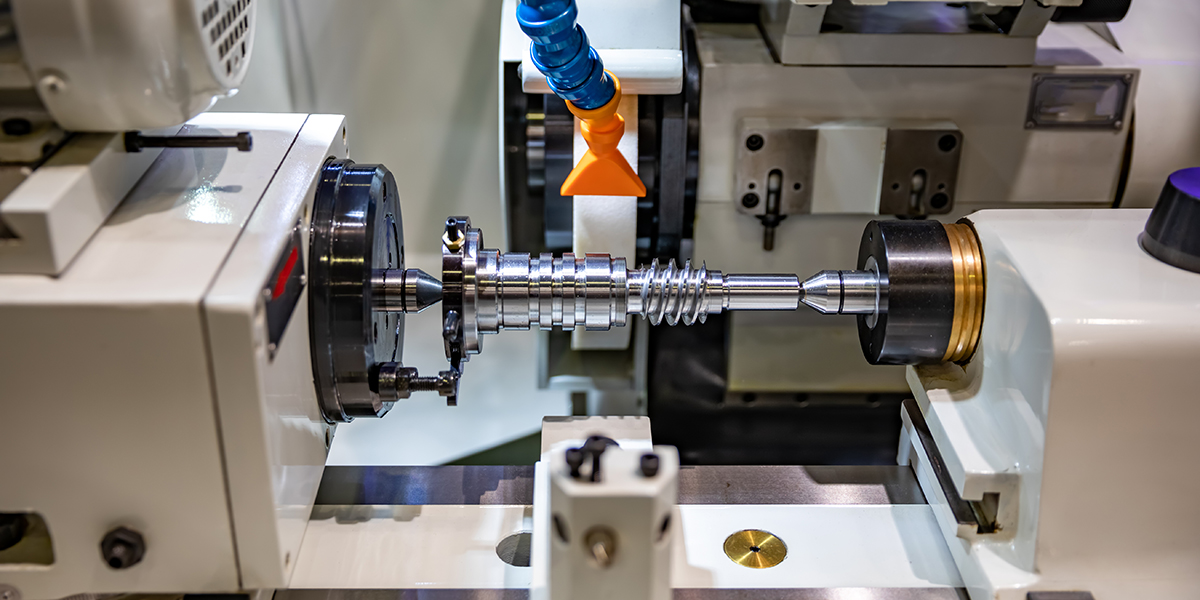

Short run production, or small-batch production, is a manufacturing method that focuses on creating limited quantities of products.

It’s not uncommon for traditional production runs to include thousands or even tens of thousands of parts. Short runs consist of a couple hundred or just a handful of parts. Therefore, it is more flexible. We can respond to market demands faster, test designs, and meet unique specifications.

Unlike mass production and its large-volume standardization, short runs are adaptive. And, because they produce fewer parts, this means lower upfront costs and more options to customize. This means when you need to respond to a trend or you just need a few parts, a short run is in order.

Advantages of Short Run and Small Batch Production

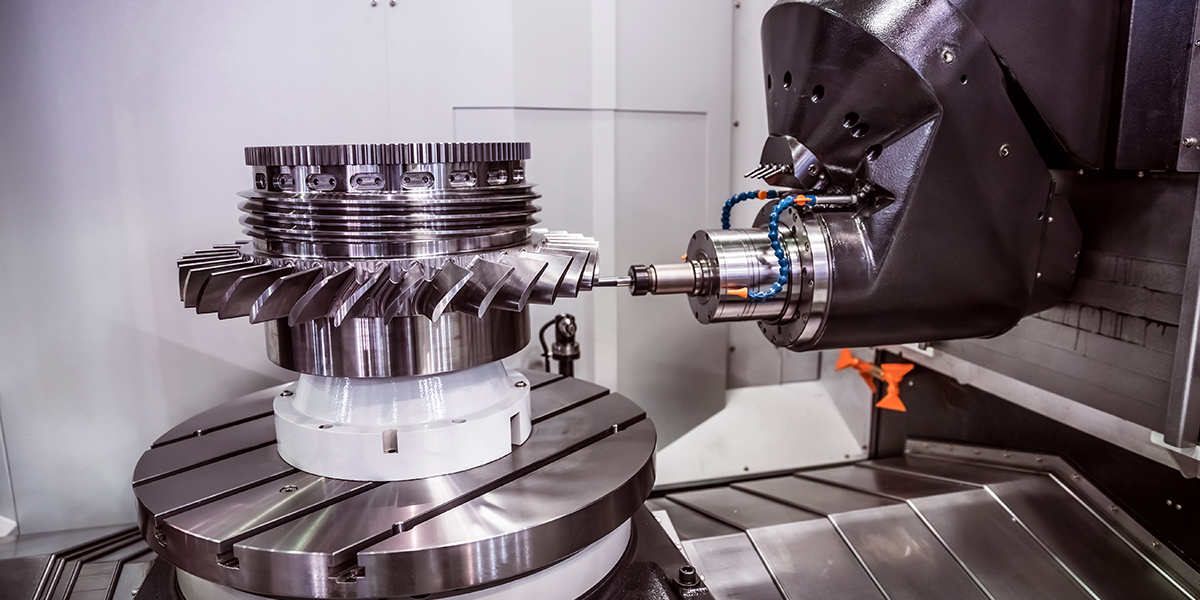

- Flexible Production: Adapt to market trends or modifications in customer preferences. Customize at a level mass production simply can’t. Stay ahead in your market.

- Cost Efficiency: Save on raw materials and reduce inventory holding costs. Better manage your resources. Minimize waste and redundancy.

- Risk Mitigation: Launch new products with less risk. Test the market without committing massive resources. Iterate on design and functionality with real-world feedback.

Quiz Yourself!

Put your knowledge to the test. Which production run would be best for each situation?

[forminator_quiz id=”3803″]

Vendor-Managed Inventory as a Procurement Strategy

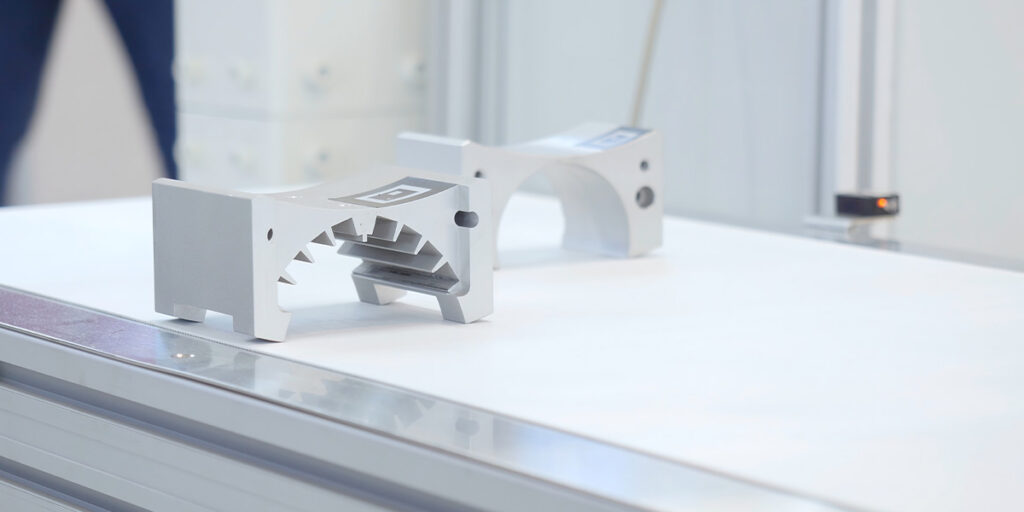

Efficient procurement is an essential component of small-batch production. So, how can you do it?

Vendor-managed inventory (VMI) is a strategy where the supplier takes responsibility for maintaining an agreed inventory of the material, typically at the buyer’s location.

VMI offers advantages for both long- and short-run production. Here’s why:

- Reduced inventory costs

- Improved efficiency

- Stronger supplier relationship

- Faster response to market changes

For more information, check out this article on how vendor-managed inventory works under the hood.

No Matter the Run, Winndeavor is on Your Side!

For manufacturing engineers and procurement specialists seeking greater flexibility and efficiency, small-batch production offers a powerful solution for adapting to market trends and meeting specific customer needs. Unlock a more responsive and resilient supply chain. Contact the Winndeavor team for any scale of production run and discover the benefits today.