We have long boasted of Computer Numeric Control’s versatility for all kinds machining projects, but if you’re still not convinced, you may want to know more about the hard-and-fast facts: what does CNC machining have to offer you? We’re glad you asked. Let’s dig in and check out the advantages CNC has to offer manufacturers.

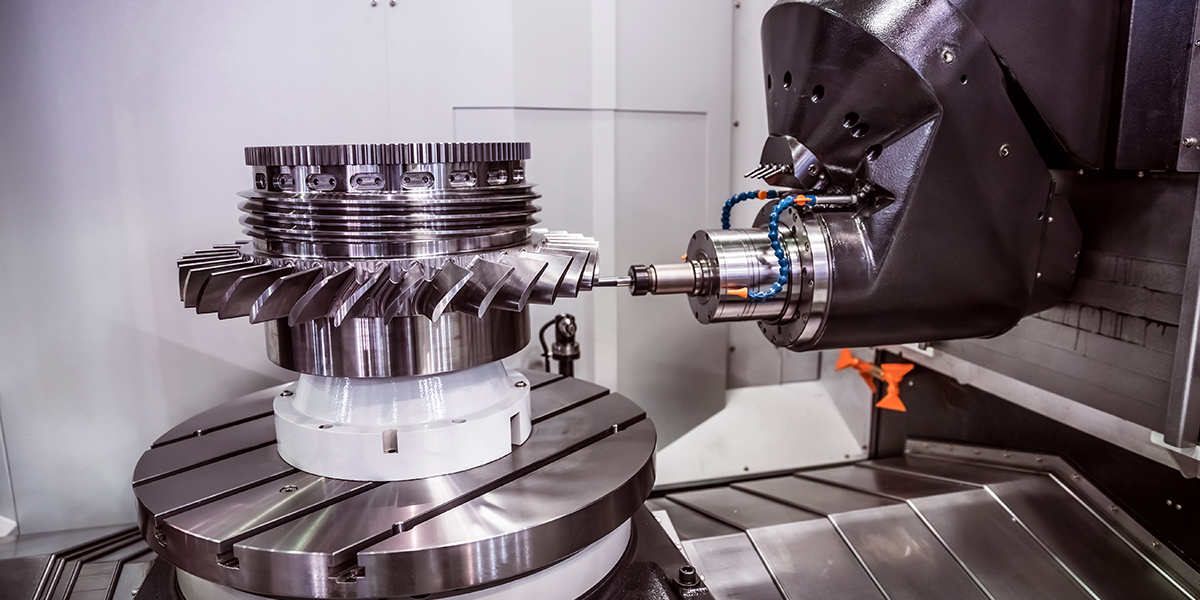

Click Here to Read: The Ins And Outs Of 5-Axis Machining

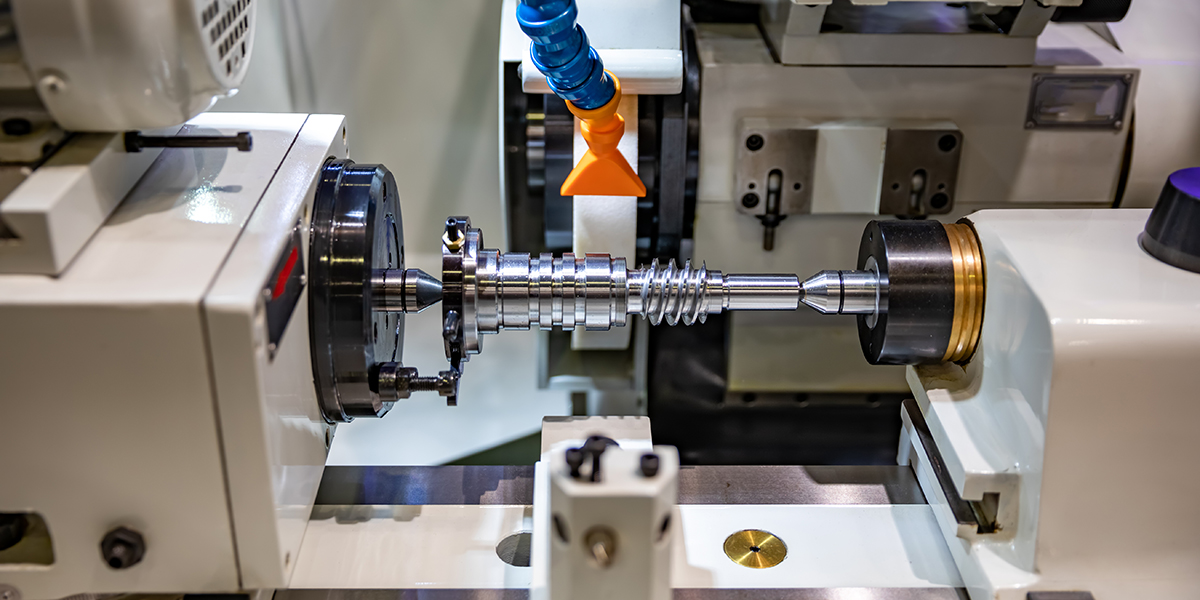

The first advantage of CNC machining is the many industries it finds itself being applied in. CNC machines can be found on the production floors for aerospace, automotive (Click Here to read CNC Reshapes Automotive Machining), dental, and virtually every manufacturing sector which requires precise and complex cuts for their plastic and metalworking.

Still not convinced? Alright, let’s get a bit more specific.

CNC machining is a speedy process. The machine can cut unnecessary steps when it produces a specific part. When you need more parts made, CNC can not only make these parts in less time, but, in addition to the removal of any potential human error, CNC improves the shop’s automation. By removing the need for a human operator, CNC machines can run attended even after hours, which also allows human operators to focus on the tasks that actually require their attention. When assembling many small or simple parts, a machine can even run overnight, so when you return to your shop the next day, you get to enjoy the fruits of the machine’s continuous work and assembly can begin immediately. Additionally, when human operators can have their distance from heavy machinery shop safety is increased: should a jam or any other error occur, the operator will not be holding the tool when it occurs. This reduces the risk of injury.

A properly functioning CNC machine works perfectly over a long period of time without needing to fix parts or repair the machine. This keeps the expenses of production costs low. Manufacturing can take a toll on any company’s budget, but CNC is an investment that pays off in the long run.

CNC machining prevents variations in long runs of the same part.

But CNC’s most distinguishing advantage is its precision. CNC removes the slight variations that even the best human operators can’t prevent. When the computer is making these precise movements and cuts, it produces the exact same result every single time. This allows you to have absolute certainty that every part will be the same, but it also illuminates the risk of CNC: if there is an error in the program, then this error will be present in every single part the program creates until it’s stopped and corrected. This is why having an expert programmer setting the machine on its way is critical. The machining world is highly standardized, so a single faulty cut could render the whole system unusable.

So, if you have a metalworking or manufacturing job you need done, CNC machining has no shortage of benefits that brings the industry to a level of precision, accuracy, and reliability that is needed to not only meet standards, but to exceed customer expectations. If you want to get the best out of your projects, CNC machining and the expert team of programmers at Winn Machine want to help you achieve that goal.