When it comes to delivering high-quality results, every step of the manufacturing process is crucial. What is equally important is all the work that happens before production starts. Prototyping, which involves creating a physical model of a product before it goes into mass production, is essential to ensuring each product meets the desired outcome. Let’s explore the process and advantages of prototyping that make this step so important to the machining industry.

The Process of Prototyping

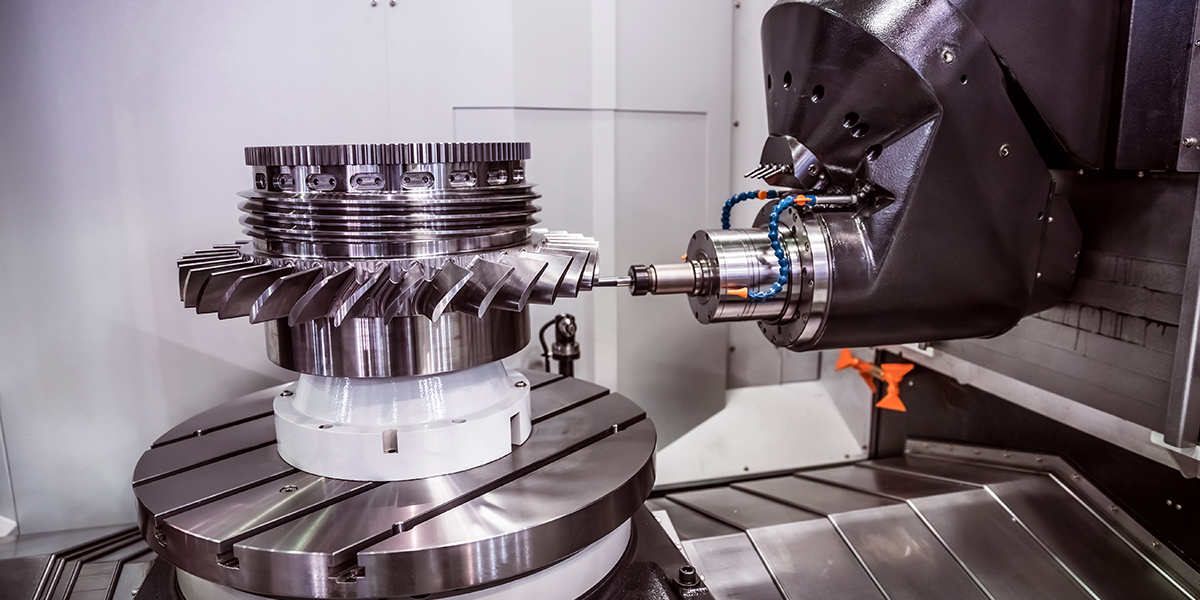

The prototyping process begins by using computer-aided design (CAD) software to create a 3D digital design. Once the design is complete, a set of instructions called a G-code is generated through a CAM process and relayed to a CNC machine. This is when the prototype is created. The prototype is then tested to ensure it meets the desired specifications and functions as intended. Any necessary adjustments are made to the design, and a new prototype is created. This process is repeated until the final product meets all specifications and is ready for mass production.

The Advantages of Prototyping

CNC machines can dial tolerances down to the micro level, ensuring that the prototype has both production quality accuracy and repeatability. This allows manufacturers to test the functionality and durability of a product before it goes into mass production. By identifying any issues early on, manufacturers can make necessary adjustments to refine the product’s quality and performance.

This benefit in turn leads to other advantages of prototyping. Identifying any design flaws before starting mass production reduces the risk of costly errors, saving money in the long run. In a similar vein, prototyping puts procedures in place to eliminate potential manufacturing issues so that the process can run smoothly and efficiently, reducing the risk of delays and increasing productivity.

Why Choose Winndeavor?

Prototyping is a crucial step in the manufacturing process that offers numerous advantages, including reducing costs, improving product quality, and increasing efficiency. At Winndeavor, we specialize in providing prototyping services for various industries, including commercial and defense aerospace, orthopedics, manufacturing, railroad and more. Working closely with our clients to ensure that the final product meets all specifications and functions as intended, our experienced team of professionals use state-of-the-art equipment to create high-quality prototypes quickly and efficiently.

Ready to take advantage of the advantages of prototyping? Contact us today to learn more about our prototyping services and how we can help you bring your product to market.