Across many industries, manufacturers go through different production cycle periods. Depending on demand, production output may yield large qualities of parts for a short time, or small batches for a long period. Manufacturers know these cycles as short run and long run production; yet there’s more to these production cycles than just time difference. Together, let’s investigate the difference between long run vs short run production to see which cycle best suits your manufacturing goals.

Know the Ins and Outs of 5 Axis Machining – Download Your Handy Infographic!

Long Run vs Short Run Production: Explained

Long run production is a long manufacturing period where orders come in varied, smaller qualities for an extended time. Production operates at fluctuating levels of activity depending on the business’ output. Typically, a long run production cycle lasts between six months to a year and may produce millions of parts.

Short run production is a much shorter production cycle where smaller batches of specialized parts are produced; however, this cycle isn’t defined by time alone. Rather, short run production is a production cycle where at least one factor of the manufacturing process is fixed, and other factors are variable. These input factors include the labor, materials, equipment, capital, and property needed to manufacture parts. A short run cycle typically lasts six months or less.

Comparing Production Cycles

So, knowing the differences between long run and short run, which one is best for you? Here are a few factors to consider:

Cost

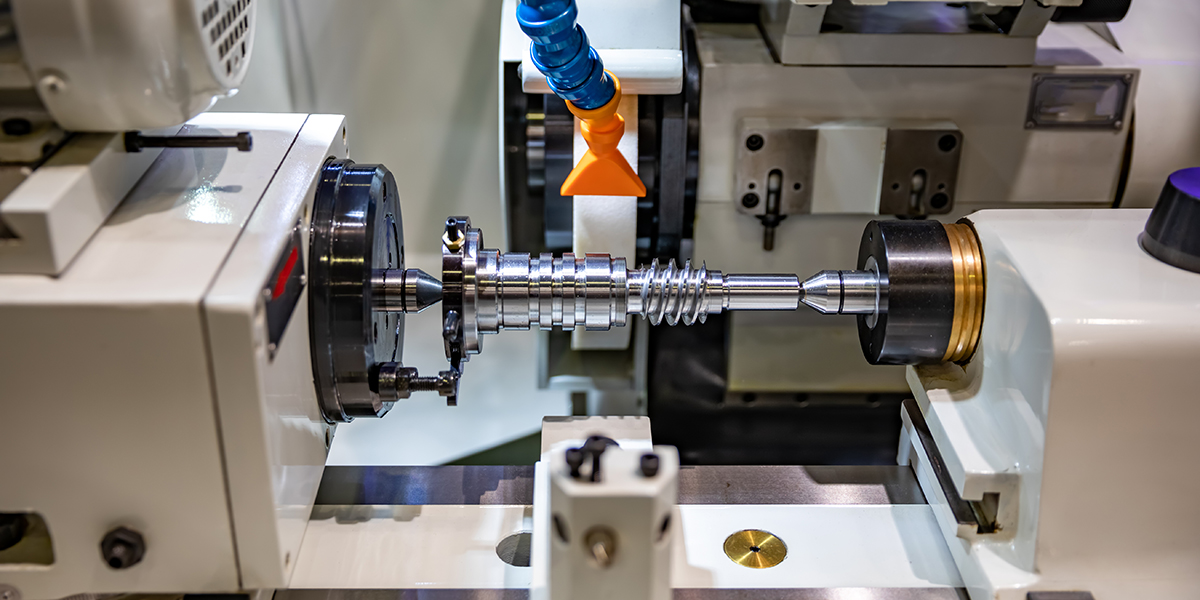

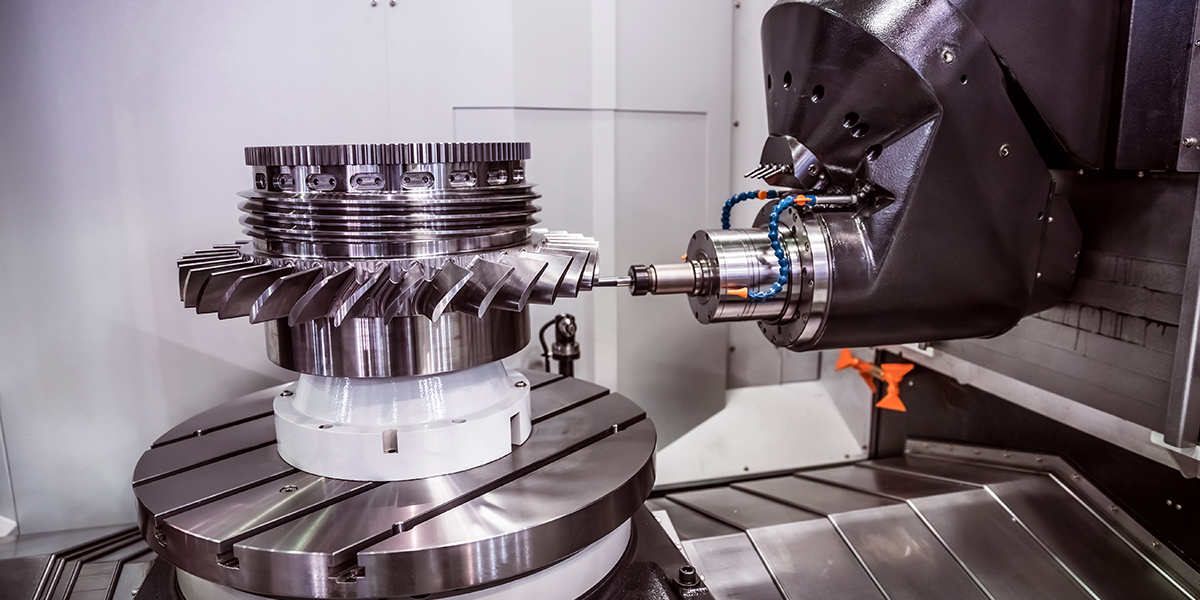

Between these two cycles, long runs have more costs involved since manufacturing variables may change throughout production, requiring machinery or designs to adapt with new orders. Since long runs last up to a year, equipment like CNC machines will need extra maintenance repairs and more materials will need to be ordered to keep up with demand.

Short run production is much cheaper since smaller order batches only require a certain amount of materials and equipment usage. This quantity control is also great for manufacturers looking to cut down on overhead capital while focusing on the quality rather than quantity of parts.

Adaptability

Although short runs are easier to set up, input factors in the production cycle are harder to change once started. Everything from materials, design specifications, specific part molds, and manufacturing tools must be established beforehand. These factors alone are expensive, so making changes after the fact may increase costs and delay production.

On the other hand, long run production enables manufacturers to pull back or push forward production as necessary to adapt to demand, allowing production to continue without delay.

Prototyping

Prototyping gives a new perspective to the long run vs short run debate. Industrial manufacturers often use prototyping to help determine if the specifications and material of parts will meet client standards. Through short run production, manufacturers can produce small batches of parts to test for quality, helping them make improvements and adjustments for any large orders.

Long run production adapts to demand, enabling manufacturers to reduce product orders if needed. Prototype testing can occur parallel to the long run production cycle, and results can be adapted to ensure the quality, quantity, and time of delivery is optimal.

Which Production Should You Run With?

Selecting the best production cycle for you ultimately comes down to the demands of your business. Small businesses with limited capital may prefer a short run due to the focus on quality over quantity; larger manufacturers with high-level demand may need a long run to keep up with their orders.

No matter your production cycle, Winndeavor will adapt to the needs of your business, ensuring quality control and improvements through precision machining. Count on our team to deliver the best results you need to meet production every time.