Precision machining stands at the forefront of aerospace advancements, enabling manufacturers to meet the industry’s exacting standards for quality and performance. As aerospace projects evolve with cutting-edge technologies, the demand for highly accurate, reliable components grows increasingly vital. This blog explores how precision machining fuels innovation in aerospace, showcasing the capabilities that make Winndeavor a trusted partner in this mission-critical industry.

Table of Contents

Understanding Precision Machining in Aerospace

Definition and Importance

Precision machining refers to the process of manufacturing components with extremely tight tolerances and exact dimensions. Techniques such as CNC machining, turning, milling, Swiss turning, and 5-axis operations allow manufacturers to produce parts that meet highly specific aerospace requirements. These methods ensure superior quality and functionality in every component.

In aerospace, even the slightest deviation in part dimensions can impact safety and performance. That’s why tight tolerances are mandatory. Our commitment to quality is reflected in our certifications, including AS9100D and ISO 9001:2015, which serve as industry benchmarks for aerospace manufacturing excellence.

The Unique Challenges of Aerospace Components

Aerospace components often feature complex geometries and require miniaturization to fit into sophisticated assemblies. Machining materials like titanium, aluminum alloys, and advanced composites poses additional difficulties due to their hardness and heat sensitivity. Precision machining directly influences component reliability and safety — essential factors in an industry where failure is not an option.

Precision Machining Technologies Powering Aerospace Innovation

Advanced CNC Machining Techniques

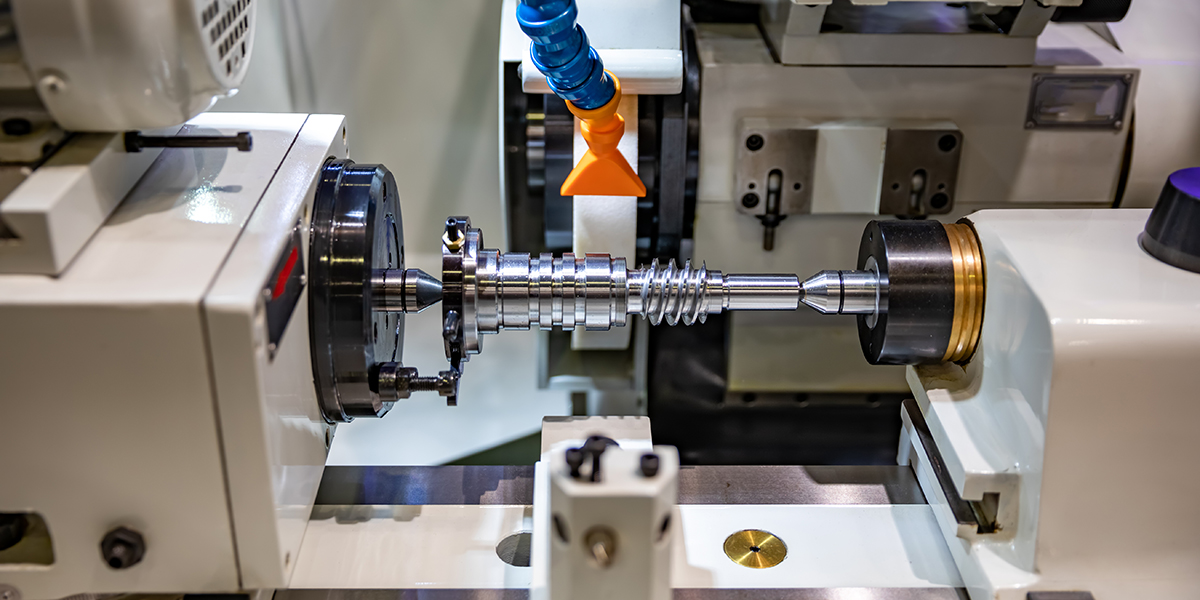

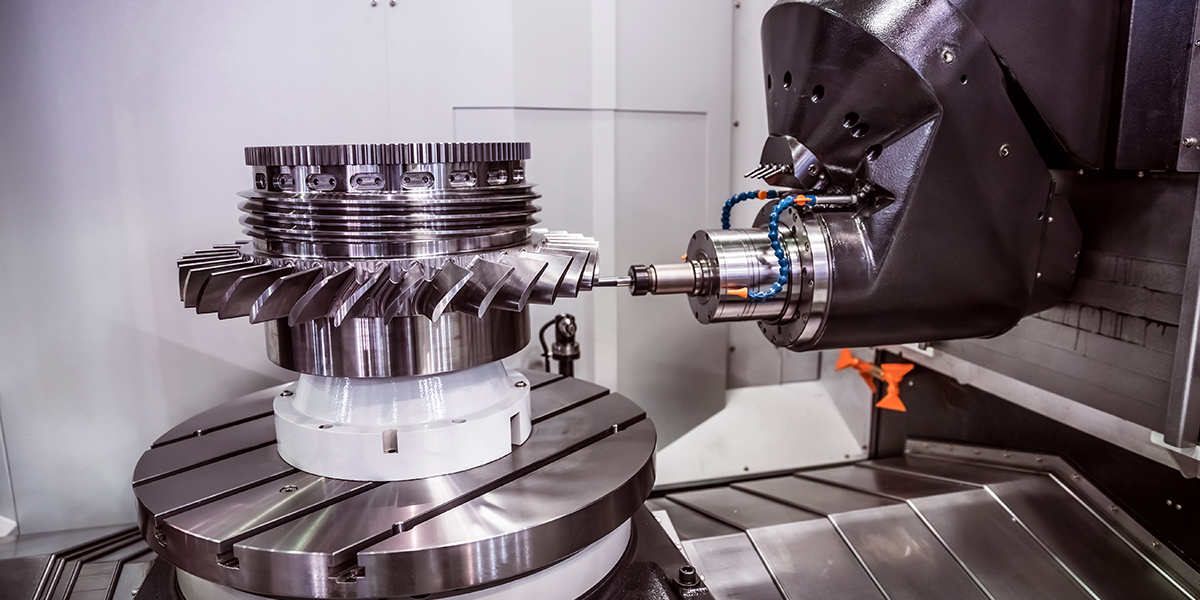

5-axis CNC machining has revolutionized aerospace manufacturing by enabling the creation of intricate components in a single setup, improving accuracy and reducing assembly steps. Swiss turning excels in producing small, precision micro-components vital for avionics and instrumentation.

Automation and Programming Enhancements

Automation plays a key role in maintaining consistent repeatability and scalability when producing aerospace parts. Our customized programming is tailored to each project’s exact design specifications, ensuring that parts meet rigorous aerospace standards every time.

Quality Inspection and Assurance

To uphold stringent quality requirements, we employ advanced inspection technologies like Coordinate Measuring Machines (CMM) and laser scanning. Such tools verify dimensional accuracy and surface integrity, ensuring compliance with aerospace standards and preventing costly recalls.

Applications of Precision Machined Components in Next-Generation Aerospace Projects

Commercial Aerospace Developments

Precision-machined parts are integral in engines, avionics, and airframe structures. These components contribute to crucial improvements in fuel efficiency, reduce aircraft weight, and enhance safety. For example, lighter and stronger turbine blades can increase engine performance while lowering emissions.

Defense and Space Exploration Innovations

In military aircraft and spacecraft, precision machining produces components capable of withstanding extreme environments such as high temperatures, pressures, and radiation. These critical parts enable advanced weapon systems, stealth technologies, and space exploration missions to operate flawlessly.

Emerging Aerospace Trends and Their Machining Needs

New trends like electrification, unmanned aerial vehicles (UAVs), hypersonic flight, and additive hybrid manufacturing demand even greater precision and material expertise. Winndeavor stays ahead by continuously adapting to these emerging requirements, supplying industries with leading-edge component solutions.

Decades of Combined Experience and Expertise

Winndeavor embodies over 95 years of combined machining experience inherited from historic powerhouse shops. This depth of knowledge ensures expert handling of the most complex aerospace projects.

State-of-the-Art Facility and Equipment

Operating from a 30,000 sq ft facility equipped with 28 advanced machines, Winndeavor optimizes efficiency and precision. Their capabilities include cutting-edge 5-axis machining and Swiss turning, suited for scalable aerospace production.

Comprehensive Services to Support Aerospace Projects

Whether you need prototyping, short runs, long production runs, vendor-managed inventory (VMI), or assembly services, Winndeavor offers a full-service approach. Close collaboration with engineering teams ensures maximum manufacturability and cost-effectiveness.

Verified Quality and Trusted Partnership

Customer testimonials routinely praise Winndeavor’s reliability, quality, and responsiveness in aerospace collaborations. This trust underscores their role as a dependable partner in mission-critical aerospace manufacturing.

Future Outlook: Precision Machining’s Impact on Aerospace Innovation

Evolving Industry Standards and Machining Capabilities

Winndeavor continuously invests in technology upgrades and process improvements to meet and exceed future aerospace demands, ensuring their clients remain competitive.

Sustainability and Efficiency Through Precision

Precision machining not only optimizes component performance but also minimizes material waste and energy usage during production—contributing to a more sustainable aerospace industry.

Collaborative Innovation with Aerospace Engineers

By partnering closely with aerospace engineers, Winndeavor helps push the boundaries of design and manufacturing — driving innovation in this dynamic field.

Ready to Elevate Your Aerospace Projects with Precision Machining Expertise?

Contact Winndeavor today to discuss how our advanced capabilities and dedicated team can deliver mission-critical components that meet your exacting standards. Visit Winndeavor Machining Services or call us to get started!