Manufacturing has undergone vast transformations since the dawn of the Industrial Revolution, but few advancements have reshaped precision manufacturing quite like multi-axis machining. This technology enables the production of complex geometries once thought impossible, pushing the boundaries of design.

At Winndeavor, our foundation lies in embracing these technological evolutions—from 3-axis pioneers to today’s cutting-edge 5-axis machines—ensuring unparalleled precision and reliability for our customers.

In this blog, we’ll explore the fascinating history of multi-axis machining technology: its origins, major milestones, and how it has revolutionized modern manufacturing.

The Origins of Machining: From Manual Tools to Early Machines

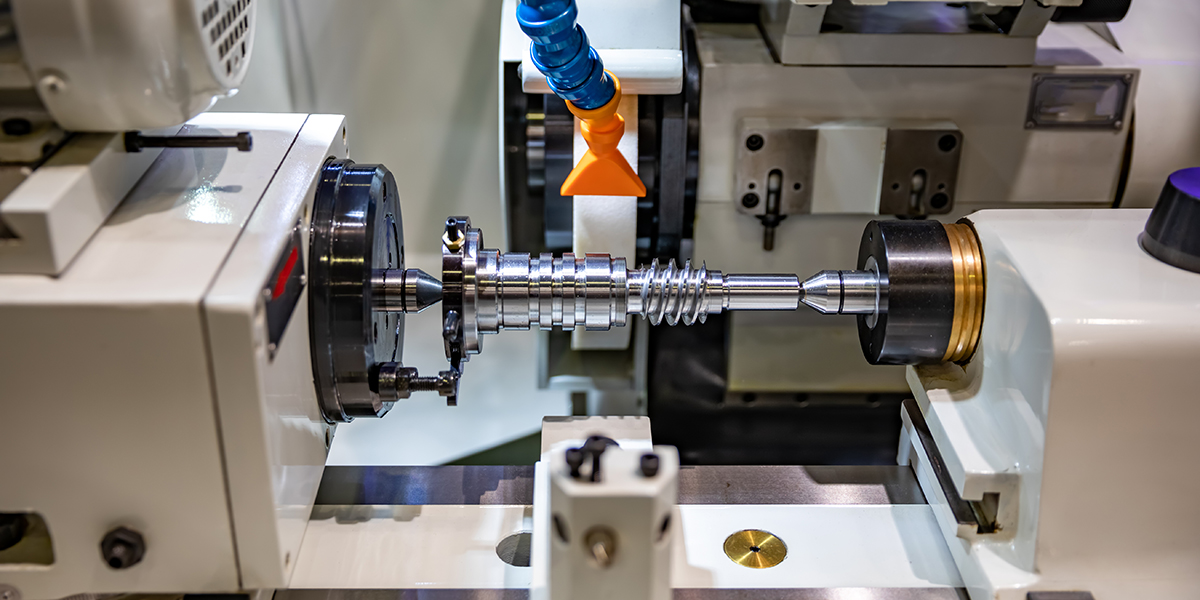

Before automated machining, manufacturing was primarily a manual process. Craftsmen used hand tools and rudimentary lathes to shape metal and wood into parts. During the late 18th and early 19th centuries, engineered machinery emerged, including the first turning lathes and milling machines, which laid the groundwork for controlled metalworking.

These early machines typically moved along one axis: either moving vertically or horizontally while the workpiece rotated or stayed still. This limited motion meant simple geometries required significant operator skill.

Machining is Computerized

A major leap forward came in the 1940s and 1950s when computer numerical control (CNC) technology began integrating with machining. Developed originally for military and aerospace applications, CNC enabled machines to follow programmed instructions for motion, dramatically improving accuracy and repeatability.

Early CNC machines typically operated on two axes (X and Y), allowing for precise 2D cuts. While revolutionary, these machines were limited to flat parts with simple geometries. Production times improved, but complex shapes still required multiple manual setups.

Enter 3-Axis Machining: Adding Depth and Complexity

The next breakthrough was the development of 3-axis machining, which added the Z-axis movement. Now, tools and parts could move vertically in addition to horizontal directions, enabling full 3D shaping.

3-axis machining became the industry standard for decades, widely adopted due to its balance of complexity, cost, and flexibility. It allowed manufacturers to produce everything from automotive parts to medical devices with greater speed and precision than before.

However, 3-axis machines still required multiple setups to reach undercuts, angled surfaces, and complex geometries, imposing limitations especially for aerospace and high-precision industries.

The Rise of Multi-Axis Machining: 4- and 5-Axis Innovation

To overcome the inherent constraints of 3-axis machines, engineers began integrating rotational axes, leading to 4-axis and eventually 5-axis machining.

4-Axis Machining

This introduced a rotational axis, allowing parts to turn during machining. For example, a workpiece could rotate around the X-axis, enabling the tool to reach more of the part’s surfaces without repositioning manually. This innovation reduced setup times and improved machining accuracy dramatically.

5-Axis Machining

The pinnacle of multi-axis technology, 5-axis machines add two rotational axes, usually the A and B axes, which work in tandem with the linear X, Y, and Z. This allows for near-universal access to part surfaces in a single setup. Components with complex curves, undercuts, and tight tolerances—like turbine blades or implantable medical devices—became feasible and more cost-effective to produce.

Comparing 3-, 4-, and 5-Axis Machining

Choosing the Right Process

Choosing between these options depends on your part’s geometry, precision needs, production volume, and budget.

The Impact of Multi-Axis Machining on Today’s Manufacturing Landscape

The evolution of multi-axis machining reshaped industries by enabling:

Unmatched Precision

Unmatched Precision

Achieve tighter tolerances and complex surface finishes.

Efficiency Gains

Efficiency Gains

Reduce manual setups, tooling changes, and lead times.

Design Freedom

Design Freedom

Manufacture complicated geometries previously impossible or cost-prohibitive.

Cost Savings

Cost Savings

Consolidate operations, minimize errors, and improve yield.

These benefits ripple across aerospace, defense, medical device manufacturing, and many other sectors that demand excellence.

Looking Ahead: The Future of Multi-Axis Machining

Emerging trends such as automation, AI-driven programming, hybrid additive-subtractive machines, and real-time adaptive controls promise even greater advancements. At Winndeavor, we continuously explore these innovations to keep delivering superior machining capabilities long into the future.

Winndeavor’s Legacy: Embracing Multi-Axis Machining

From simple hand tools to today’s sophisticated 5-axis CNC systems, the history of multi-axis machining is a story of relentless innovation driving precision and complexity in manufacturing. Understanding this evolution sheds light on why modern machining processes are critical to achieving quality, efficiency, and flexibility in today’s demanding industries.

If your project requires expertise in advanced machining technologies, contact Winndeavor today. Let us show you how decades of combined experience and cutting-edge multi-axis capabilities can help bring your vision to life.

Explore our Machining Capabilities and get in touch with our experts to learn more.