Founded in 1979, Winn began life as a welding shop in the small town of Pines, near Michigan City, IN. After a few years, Winn purchased its first manual lathe and began producing turned parts for local manufacturers. In 1985, Winn acquired its first pair of single spindle screw machines and due to an increase in work demand, moved into a much larger 10,000-square-foot building. Four years later, in 1989, Winn began making their first investments in CNC machining technology, and they’ve never looked back. In 2012 they moved once more, again into a larger facility, from Michigan City to their current location in LaPorte.

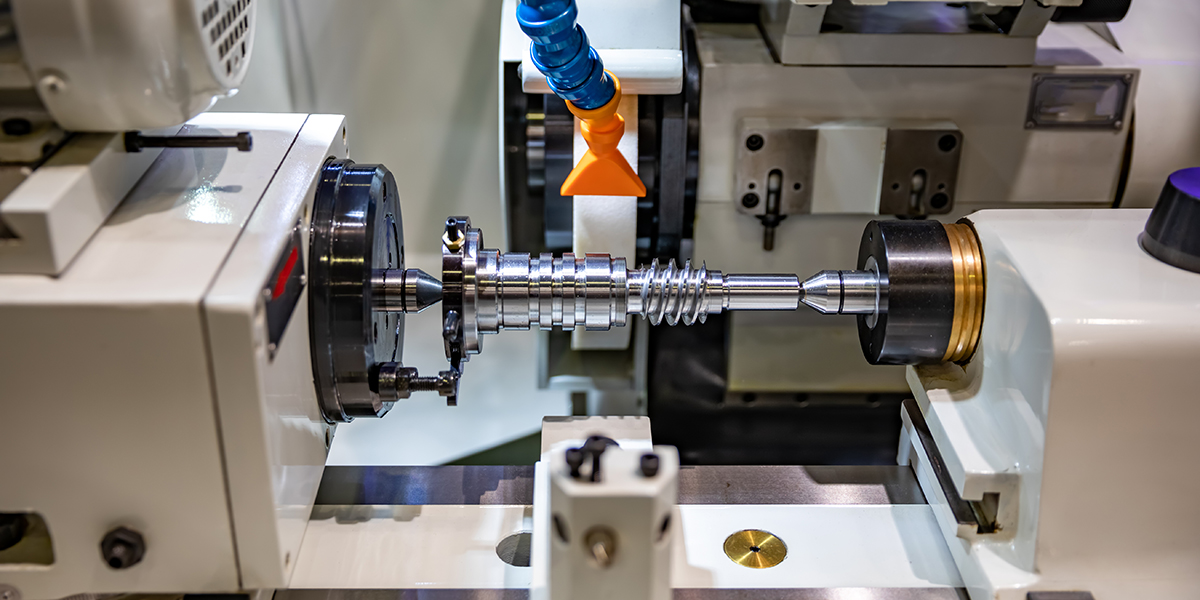

Check out our Guide to CNC Lathes

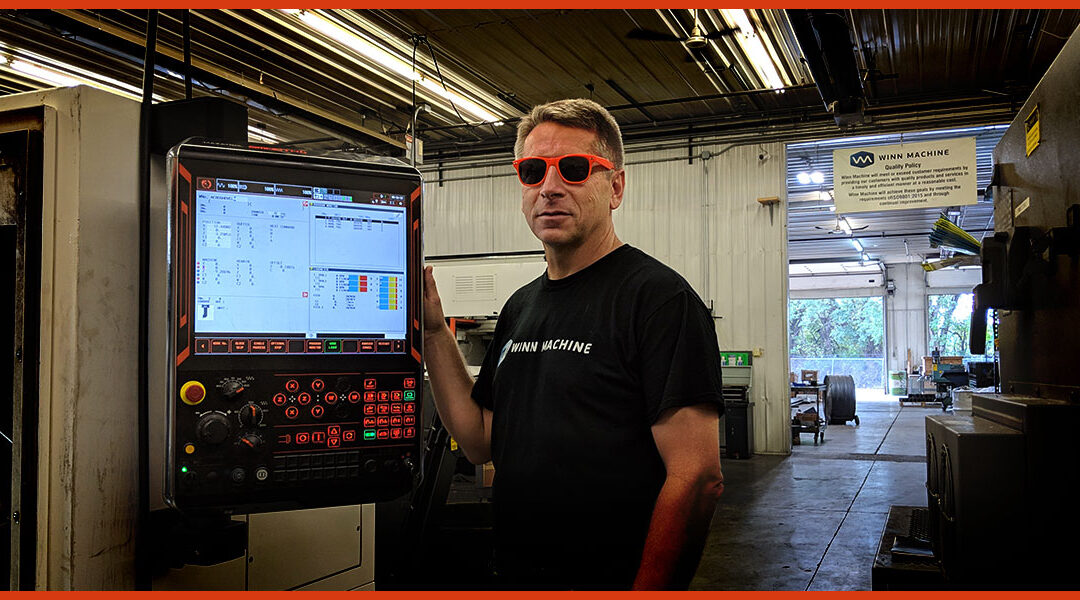

Current CEO, Damon Gasaway, has been with Winn from the early days. Damon began working for the company in 1987 — mostly sweeping floors, deburring and packing parts and helping around the shop where needed. In time, he developed a reputation for dependability and through his strong work ethic became a shop foreman in 1990. In 1999, Damon, along with his wife Dina, finalized the purchase agreement for Winn. Damon takes great pride in employing highly-trained, specialized talent and works hard to keep his team focused on providing Winn clients with quality products and exceptional service.

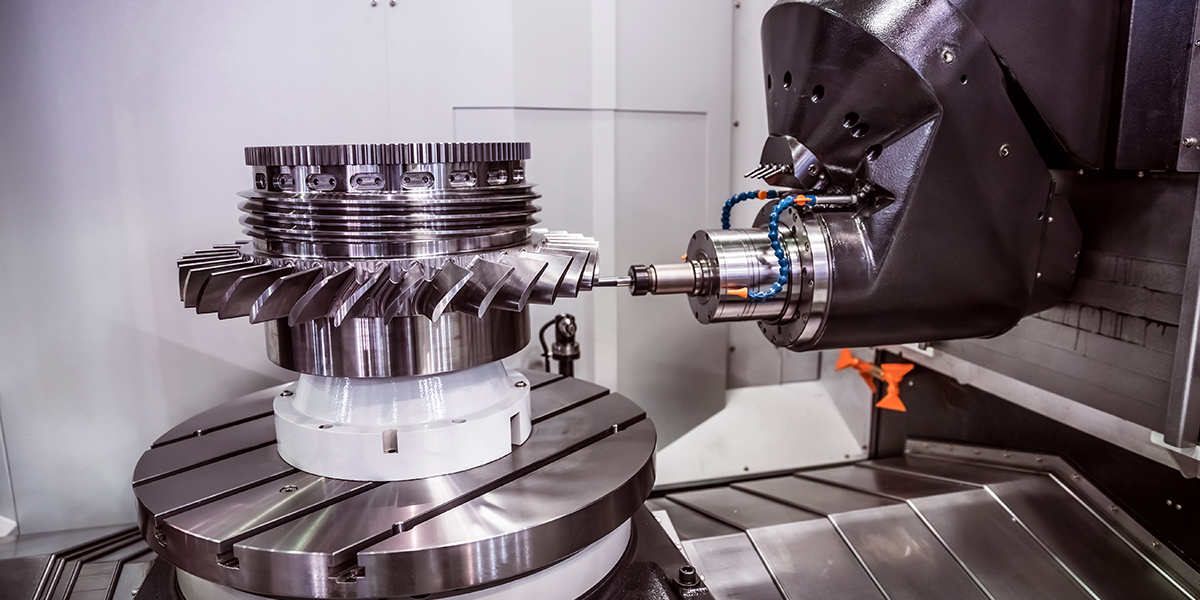

A company that started as a welding shop with a single lathe machine, now maintains 2 CNC mills, 12 CNC lathes, 2 saws, and 2 grinders. With a need for reliability, Winn utilizes six Mazak CNC machines, including:

- Mazak QTS 200 2” thru spindle capacity with automatic bar loader

- Mazak QTN 250-II MY 3” thru spindle capacity with live tooling and automatic bar loader

- Mazak QTN 250-II MSY

- Mazak QTN 250-II MSY Gantry

- Mazak Smart 530C 20” x 40” table

- Mazak Smooth VC-500A

In a very competitive industry, Winn continues to be successful by being responsive and flexible to their client’s needs. According to Damon, “Our team members are focused on over-delivering for our clients and working hard to make them happy. This sometimes means we work late and on weekends.” As Damon was told early on in his career, “’Can’t’ never done nothing.” This mentality is ingrained throughout the entire organization.

Mazak QTN 250-II MY 3” thru spindle capacity with live tooling and automatic bar loader

“I’ve worked with Winn for many years and have always been impressed with their level of customer service,” said Judy Kmiec, Global Sourcing Manager at Sullair, LLC, “from their help with product inception and drawing clarification, to quoting, to final delivery.”

Jay Sittig, Purchasing Manager at Vanair Manufacturing agreed: “Winn has been a strategic partner of ours for decades. This relationship has been based on trust, respect, and firm business practices. They have continued to improve processes and machinery as time has evolved. This has allowed us to stay competitive in our market as we can supply machines containing machined components of the highest quality. I could not have asked for a better long-term partner to work and grow with.”

Ecologically conscious, Winn, an ISO 9001 certified manufacturer, also recognizes their responsibility to conduct business in a way that protects and improves the state of the environment for future generations. They understand that the long-term well-being of society, the well-being of their employees, the strength of the global economy and the continuing success of their own business depends on their commitment to reducing waste, encouraging and promoting healthy behaviors and working every day with the mindset of continuous improvement.

What’s the future look like for Winn? Well, with the rapid and continual advancements in machining and automation, Damon anticipates seeing growth in production with limited need for hiring. Winn continues to expand their client base into other industries by delivering on their promise of precision-machined parts and excellent customer service. One thing is for sure — America’s machining heritage is alive and well in LaPorte, IN.