The aerospace manufacturing industry is constantly evolving and advancing. The industry has seen the development of several important processes in recent decades. These processes do everything from forming parts to finishing parts and materials. While there is a long list of critical aerospace manufacturing processes, anyone in the industry should be familiar with these 5 processes:

Check out our Guide to CNC Lathes

Aerospace Manufacturing Processes

1. Milling

Milling is one of the most common machining processes in the aerospace industry; it’s most often used to create cuts within a work piece. These cuts can range from simple lines and shapes to more complex designs and detailed layers. The most common milling processes include:

- Vertical Milling

- Horizontal Milling

- Side Milling

- Form Milling

- Face Milling

The type of milling process used depends on the material and the needs of the finished part.

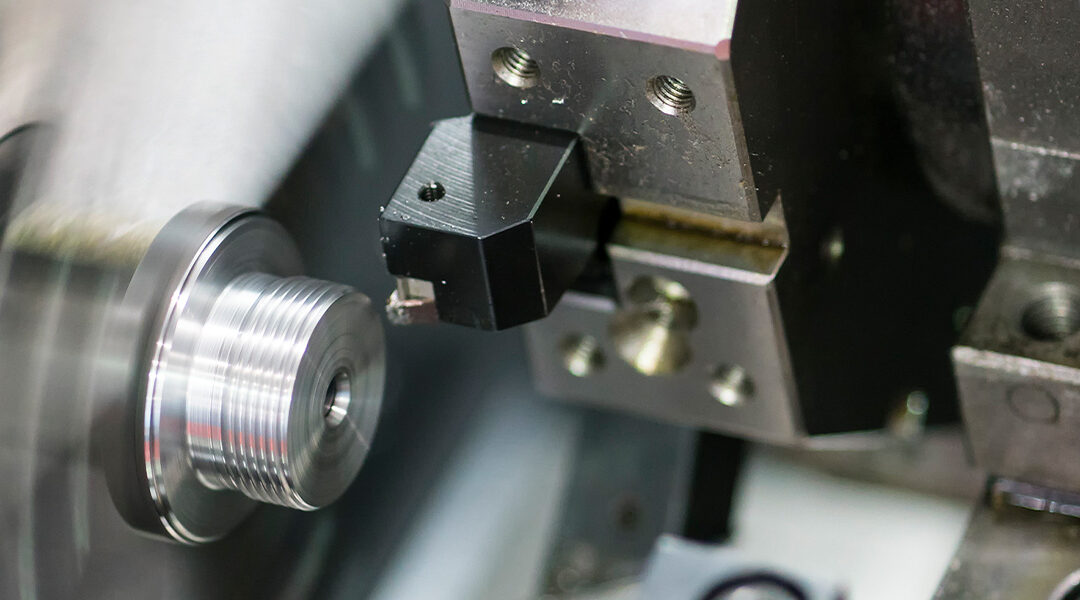

2. Swiss Turning

The Swiss machine’s popularity has grown over the years thanks to its ability to turn smaller and more complex workpieces. Swiss turning also produces long runs of parts quickly and often cheaper than other turning methods.

The barstock of a Swiss turning machine spins and slides through a guide bushing. This provides a strong point of support, allowing for workpieces of various lengths. This also provides the support needed to create smaller more intricate details within the workpiece.

3. Hard Turning

Hard turning is a finishing process with several advantages over other methods. Because the fundamentals of hard turning are similar to other “soft turning” methods, machinists are often able to quickly learn to apply their skills to hard turning. Other finishing processes like grinding often require specialized training. When you need to finish complex workpieces or both the internal and external geometries, hard turning is the solution you need.

Centerless grinding is one of the many processes used to fine-tune cylindrical workpieces.

4. Grinding

During the grinding process, the workpiece is smoothed out and irregularities are removed. This keeps the workpiece consistent with other pieces produced. Grinding has an advantage with its ability to be used on most types of workpieces, regardless of their shape or size. Many clients within the aerospace industry will require grinding from the manufacturer for the finishing of their product.

Like other finishing and machining methods, there are many types of grinding processes. The most common grinding processes include:

- Cylindrical Grinding

- Form Grinding

- Surface Grinding

- Centerless Grinding

5. 5-Axis CNC Machining

The key to 5-axis CNC machining comes from advancements in technology that allow for more sophisticated machines to craft parts in 5 and 6 axes. 5- and 6-axis CNC machining allows both the workpiece and the tool head to move, rotate, and tilt within the machine to craft hard-to-reach areas and shape complex geometries. In the aerospace industry, where every micrometer counts and parts are put into systems which demand perfection, 5- and 6-axis machining promotes the exacting quality you need.

These are just some of the many processes used in the aerospace manufacturing industry. Each one has its purpose and place in the overall production process. Winn Machine is proud to offer several of these techniques and processes, plus more not listed here, in our machine shop. To learn more about the products and services we offer, contact us today!