Any manufacturer worth their salt knows automation has become an integral part of the industry, revolutionizing the way products are made. Through advanced technologies, manufacturers now utilize a wide array of tools and systems to streamline their operations and enhance productivity. Let’s take a closer look at the benefits of automation in manufacturing and the innovative tools we’re using to improve the manufacturing process.

Streamline Inventory Management – Download Your Comprehensive VMI Checklist!

The Benefits of Automation in Manufacturing

Automation helps improve the manufacturing process in several ways:

Increased Productivity

Automation replaces repetitive, time-consuming tasks with fast and precise automated operations. The result is greater productivity, and more parts in less time.

Enhanced Precision

Automated tools ensure operations are performed with unrelenting accuracy, eliminating human error and yielding high-quality products. Precision machining not only enhances product quality but also reduces material waste, enhancing cost-effectiveness.

Improved Safety

Automated tools create a safer working environment because they remove the need for human involvement in potentially hazardous machine areas, reducing the risk of workplace accidents and injuries.

Automation Tools Used in Manufacturing

There are a wide range of automation tools available to manufacturers to help streamline the manufacturing process. Here are some of the tools we use at Winndeavor:

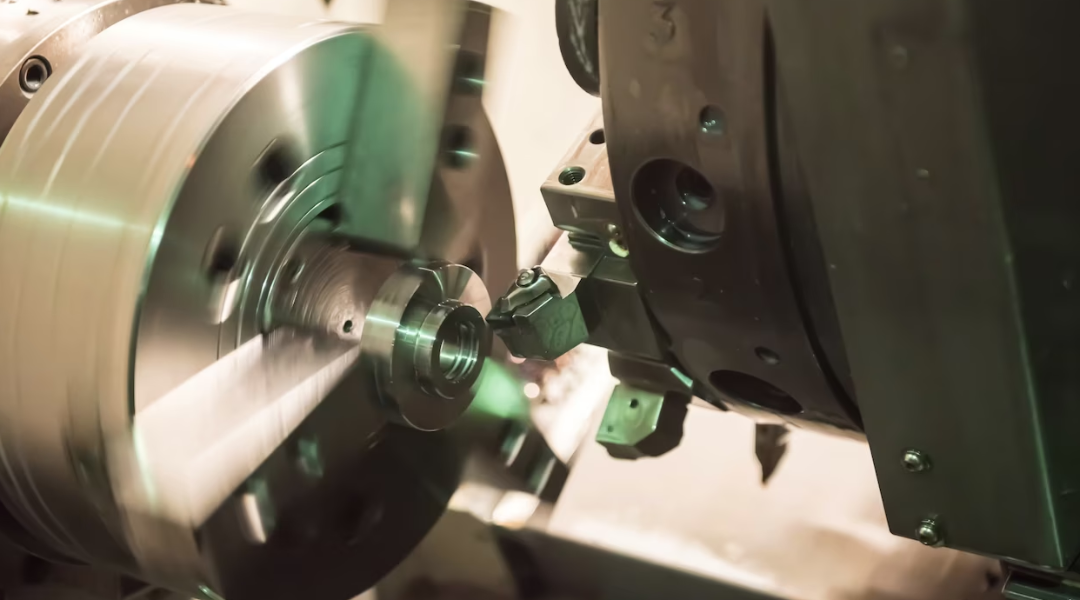

Bar Feeds

Bar feeds are crucial when working with lathes. These devices automatically load and feed raw material into the lathe. By automating the feeding process, manufacturers achieve higher efficiency, reduce downtime, and improve overall productivity.

Part catchers are just one of the many tools used for automation in manufacturing to help streamline workflow.

Part Catchers

Part catchers (also known as part unloaders) are automated systems designed to remove finished parts from the machining area. These devices reduce the manual labor required for a smooth workflow. Additionally, part catchers minimize the risk of errors, promoting worker safety.

Robots

Perhaps one of the most prominent automation tools used in manufacturing, robots have become increasingly popular in the manufacturing industry due to their versatility and efficiency. They are able to perform various tasks such as material handling, assembly, and even complex machining operations.

Palette Changers

Palette changers are used in milling machines to facilitate the quick exchange of workpieces. They enable seamless transition between different jobs, reducing downtime and maximizing machine utilization. With the ability to automate the handling and swapping of workpieces, palette changers enhance efficiency and enable manufacturers to meet tight deadlines.

Winndeavor: Manufacturing for the Future

Winndeavor recognizes the crucial role automation plays in modern manufacturing. That’s why we combine cutting-edge automation tools and systems with meticulous human care and craftsmanship to deliver premium results. By embracing the tools of the future, we ensure efficient production processes, consistent quality, and timely delivery of machined parts. Our commitment to exceptional precision, customer satisfaction, and cost-effectiveness drives us to leverage the benefits of automation while maintaining a personal touch through our skilled workforce. If you’re ready to experience a better way of manufacturing first-hand, reach out to our team today and take the first step toward a successful and profitable manufacturing partnership.