Steel is a powerhouse material for precision machining. Known for its exceptional strength, durability, and versatility, it’s no wonder that manufacturing steel products is a request from many suppliers. However, it’s important to remember that just because a material has many great qualities, it doesn’t mean it’s the right material for your project. To better understand if manufacturing steel products is the best solution for you, let’s take a closer look at the advantages and disadvantages of working with steel, the different options within this category, and how you can determine the perfect choice for quality finished products.

Stay Ahead of Supply Chain Issues with Our Helpful Infographic!

Manufacturing Steel Products: The Advantages

Using steel in precision machining brings several advantages that contribute to superior performance and reliability:

- Strength and Durability: Steel is incredibly strong and long-lasting, making it ideal for applications requiring components to endure rigorous operating conditions. Its durability ensures longevity and reduces the need for frequent replacements.

- Machinability: Steel’s machinability allows for precise shaping and intricate detailing, especially if it’s a steel with a low amount of carbon. This results in tight tolerances and dimensional accuracy, making for high-precision parts.

- Versatility: With a wide range of grades and variations, steel is a versatile material that can be tailored to meet specific requirements across various industries and applications, including automotive, aerospace, and medical.

The Disadvantages

While steel is a highly favored material for precision machining, it does have a few limitations to consider.

- Cost: Compared to some other materials, the production cost of steel products can be relatively higher. However, the durability and longevity of steel often make it a cost-effective choice in the long run.

- Weight: Because of steel’s high strength-to-weight ratio, its use may be limited in certain applications where weight reduction is vital. However, its exceptional strength makes it highly suitable for situations where structural integrity and load-bearing capacity are paramount.

- Corrosion: Steel is more susceptible to corrosion than some other metals such as aluminum or titanium. For applications subjected to harsh environments or corrosive substances, additional protective measures may be necessary.

When deciding if manufacturing steel products is the right option for you, think about what you require from your project, what conditions the parts will be exposed to, and how its capabilities will work with or against your end goal. If moving forward with steel, don’t forget to factor in…

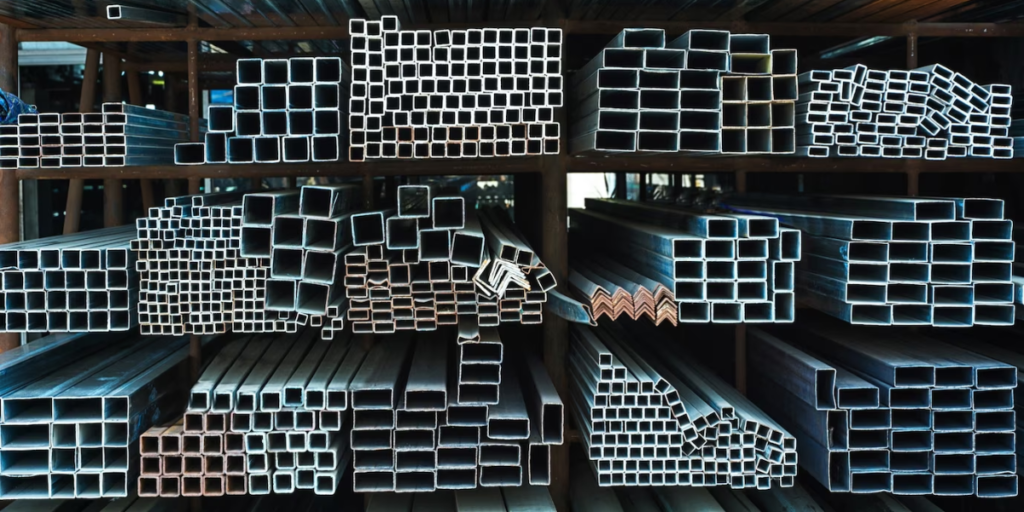

The Types of Steel

Consider which type of steel you’ll want to use when manufacturing steel products.

Not all steels are the same. Depending on the internal makeup of the material, one steel may be more suitable for your project compared to another. Here are some of the common types of steel used in precision machining:

Tool Steel

Tool steel is recognized for its outstanding hardness, wear resistance, and toughness. It is primarily employed in the production of cutting tools, dies, and molds where exceptional strength and durability are required.

Stainless Steel

Stainless steel contains a minimum chromium content of 10.5%; when it reacts with the oxygen in the air, it forms a protective layer on the material’s surface. So, unlike other steels, it has remarkable corrosion resistance, making it perfect for applications where hygiene, durability, and aesthetics are paramount. It finds applications in medical instruments, food processing equipment, architectural components, and more, ensuring product integrity and longevity.

Alloy Steel

Extremely versatile, alloy steel incorporates various elements like manganese, chromium, or nickel so properties such as strength, toughness, and heat resistance can be customized. Because of this, alloy steel is widely used across many applications.

Should You be Manufacturing Steel Products?

Steel products play a vital role in precision machining, offering unmatched strength, durability, and versatility. While the advantages of manufacturing steel products are plentiful, it is important to consider all the factors that go into this resource and if they are best suited for your project.

At Winndeavor, we take pride in our expertise in manufacturing products that meet the highest industry standards. We’ll work with you and guide you to the best material for your needs. We also implement rigorous quality control measures, so all finished products not only meet, but exceed expectations. Contact us today to experience our commitment to using the best materials for you and delivering superior steel manufacturing products. Want to learn more about your options? Read our article on the best metals for machining.