When we talk about manufacturing and making parts, the ability to execute on long-run production is critical. The assembly line must be ready and equipped to make thousands, even tens of thousands of products, without interruption. So, running out of parts brings production to a halt.

This is where a long-run production strategy comes into play as a solution. With a focus on large production quantities and efficiency, it is a favorite answer when the question is “How can I make sure I have the parts I need?”

The Secrets to Success in Long-Run Production

For manufacturers in any department, the preparation stage for a long production run can make the difference between success and failure. Here are the five top secrets to mastering long-run production:

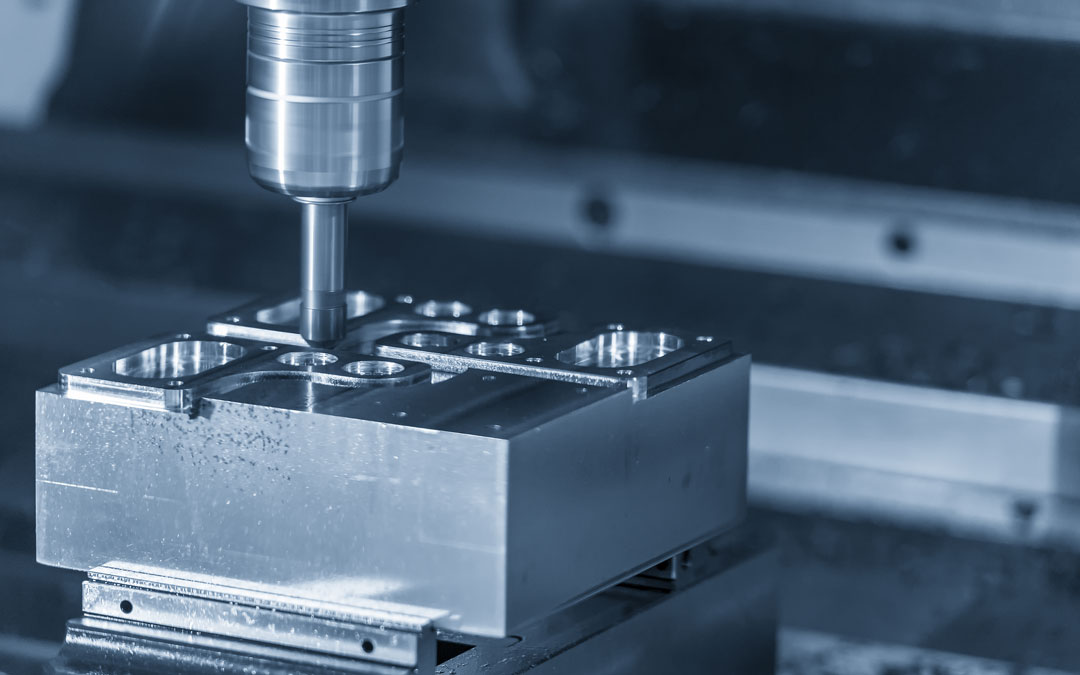

1. Process Control

Process control is the linchpin of effective long-run production. The emphasis lies on maintaining consistent quality across high volumes.

How can you do it? Establish detailed instructions and standard operating procedures (SOPs). These, coupled with in-process quality checks and inspections will mean every part is delivered at the quality needed. Plus, they will minimize the risk of rejected parts.

Secret #1: Process Control

Ensure every product meets quality standards through detailed instructions and SOPs, coupled with in-process quality checks and inspections.

2. Material Flow and Layout

Once you have your instructions in place, now you have to execute on the shop floor.

Does raw material zig-zag across your shop as it’s worked? How much time could you save by reducing the travel distance from one stage of production to the next? It’s time to reimagine your layout.

The right layout will reduce bottlenecks and increase the flow of materials. Making production as a whole more efficient. A smart layout plan will prime your shop for success. Read more tips about a strategic shop layout here.

Secret #2: Optimize Material Flow and Layout

Design your facility layout to minimize bottlenecks and reduce material handling distances.

3. Preventive Maintenance

In long-run production, the cost of downtime can be high. Implementing a regular preventive maintenance schedule is a crucial step for avoiding breakdowns. A maintenance plan will extend the lifespan of your equipment and ensure production can continue without unexpected delays.

Secret #3: Preventive Maintenance

Implement regular checks and maintenance routines to keep production steady and avoid costly interruptions.

4. Skilled Workforce

The role of human capital cannot be overstated in sustained production efforts. Even though robotics and CNC have allowed many tasks to be automated, you still need skilled machinists to program and run the equipment.

Investing in your workforce’s continued growth, in turn, encourages them to own their roles. A skilled, knowledgeable, and motivated workforce is a critical asset whenever you need to prepare a long production run.

Secret #4: Build a Skilled Workforce

A knowledgeable and capable workforce takes ownership of their roles, driving productivity and innovation.

5. Vendor-Managed Inventory

Finally, let’s talk about vendor-managed inventory, or VMI. This is a strategic approach to procurement that can be of great benefit for any production run.

Imagine you sign-on Winndeavor to be your vendor. As specialists in vendor-managed inventory, we will provide the parts you need when you need them. There are several benefits of this. Beyond the simple “you don’t need to make the parts yourself,” we would also make sure you don’t waste inventory space with parts you don’t need.

Secret #5: Vendor-Managed Inventory

Leverage VMI to reduce inventory costs and avoid shortages. Establish strong partnerships with suppliers to ensure a consistent and reliable supply, boosting efficiency.

Imagine you sign-on Winndeavor to be your vendor. As specialists in vendor-managed inventory, we will provide the parts you need when you need them. There are several benefits of this. Beyond the simple “you don’t need to make the parts yourself,” we would also make sure you don’t waste inventory space with parts you don’t need.

So, if you are preparing a run of 10,000 assemblies, we would give you the parts for that run, plus a few extra in case of any issues. As part of the VMI strategy, we will also proactively stock your shelves, so you always have the parts you need without overstocking. No shortages, but also no overages!

Establishing strong partnerships with suppliers creates a reliable, consistent supply of materials. This improves supply chain efficiency and responsiveness.

Team Up with Winndeavor for Your Long-Run Production

Mastering these five secrets can lead to significant improvements in long-run production efficiency. From process control to strategic inventory management, each element plays a role in building a production system capable of sustaining high-volume demands. As the industry continues to evolve, long-run production will remain constant.

Ready to enjoy the benefits of working with a VMI partner like Winndeavor for your long-run needs? Contact us and let us be your guide on the road to operational excellence!