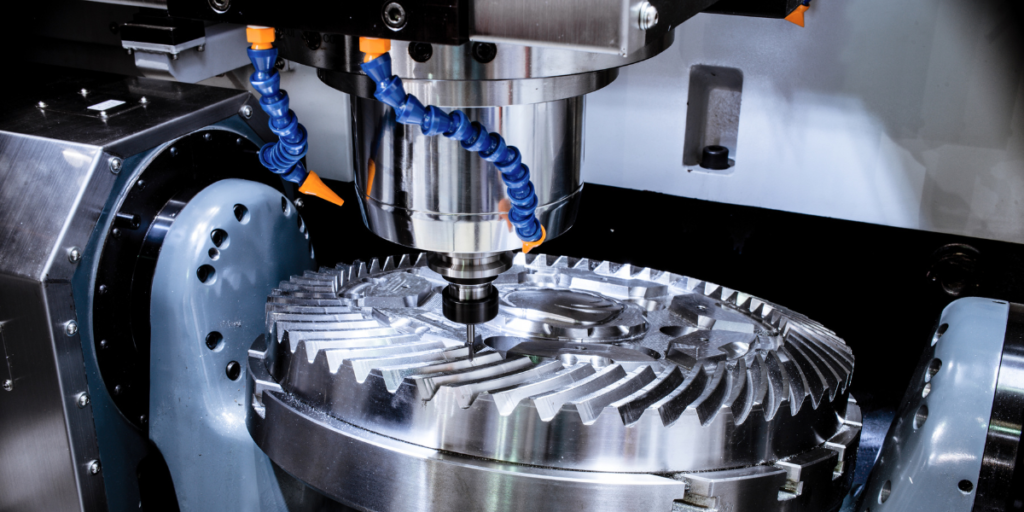

Winndeavor understands that precision machining plays a crucial role in aerospace, defense, industrial, medical, commercial, and more. Within this field, a powerhouse tool has revolutionized the way components and parts are manufactured. What is that tool? CNC. What does CNC stand for? Find out as we break down the meaning and significance behind these three letters and the advantages CNC offers over traditional manufacturing processes.

What Does CNC Stand For?

CNC stands for Computer Numerical Control and embodies an innovative approach to precision manufacturing. This technology seamlessly integrates computer programs and advanced machinery to revolutionize the production of components and parts.

How does this work? CNC machining encompasses a set of processes that leverage computer programs to precisely dictate the movements and functions performed by the machining equipment.

As Goodwin University explains, “CNC machines are essentially the opposite of ‘old-school’ devices that are manually controlled by hand wheels or levers, or mechanically automated by cams alone. Today’s modern CNC machines understand and function using CNC machining language—called G-code—which tells them precise measurements for production, like feed rate, speed, location, and coordination.”

This digital control, guided by intricate numerical codes, ensures the seamless translation of intricate designs into physical outputs. This eliminates the potential for human error and the variability associated with traditional manufacturing methods.

In essence, the integration of CNC into the manufacturing process represents a paradigm shift that redefines the boundaries of what precision machining can accomplish. By embracing CNC technology, manufacturers achieve new levels of design complexity, material versatility, and production efficiency, setting a new standard for precision and quality in component manufacturing.

Advantages of CNC Precision Machining

CNC offers a multitude of benefits, including:

- Accuracy and Consistency:

Traditional manufacturing processes are susceptible to human error. CNC eliminates the margin of error by automating tasks with unparalleled precision. With computer-guided instructions, CNC machines deliver consistent and reliable results, ensuring the highest level of accuracy for even the most intricate designs.

- Complex Designs and Versatility:

CNC technology enables the creation of complex and intricate designs that would be difficult—or even impossible—to achieve through traditional methods. The flexibility of CNC machines allows for the machining of various materials, such as metal, plastic, and wood, opening up endless possibilities for industries that require diverse components.

CNC stands for reliability when tackling complex designs.

- Efficiency and Speed:

One of the key benefits of CNC machining is its efficiency in terms of time and productivity. CNC machines execute tasks with minimal supervision, reducing the overall production time significantly. This increased speed translates into shorter lead times, enabling companies to meet tight deadlines and deliver products faster.

- Cost Savings:

CNC machining minimizes material wastage, maximizing material utilization and reducing overall costs. Additionally, the increased efficiency and productivity of CNC machines help companies optimize their operations, resulting in improved profitability.

Winndeavor: The Precision Machining Leader

When it comes to precision machining, Winndeavor is a leader in the industry. With a rich history dating back to 1979, our experts bring a wealth of knowledge to the table. Winndeavor offers comprehensive manufacturing services, including:

With our commitment to leveraging modern technology, including advanced CNC machines, we see to it that you receive the highest quality and most precise components.

What Does CNC Stand For? The Same Thing Winndeavor Does—Precision Excellence

CNC machining has transformed the field of precision manufacturing. With unparalleled accuracy, versatility, efficiency, and cost savings, CNC technology offers a superior alternative to traditional manufacturing processes. Combine this with our extensive experience and commitment to excellence, and you have the partner of choice for precision machining solutions. Contact us today to experience true precision in your manufacturing processes and discover how the combined power of CNC and Winndeavor can help you.