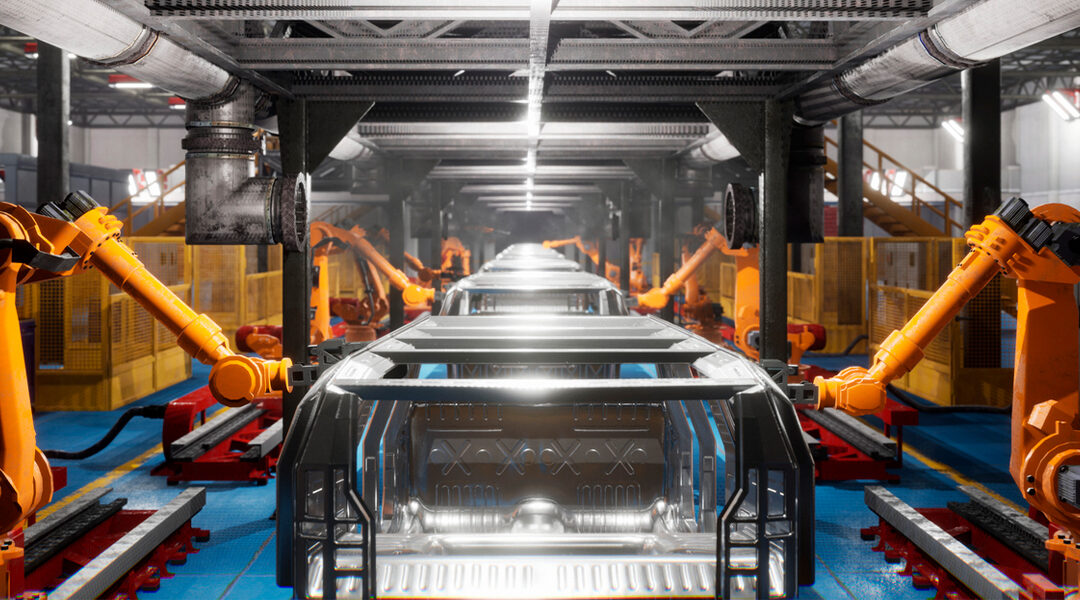

As leaders in the manufacturing world, we’re always on the lookout for the next innovation which will make our shop floor more efficient and make production cycles shorter. One of the key ways to achieve this is through the use of automation and robotics. In this blog, we will take a deeper look at how robotics have an overwhelmingly positive impact on the manufacturing sector.

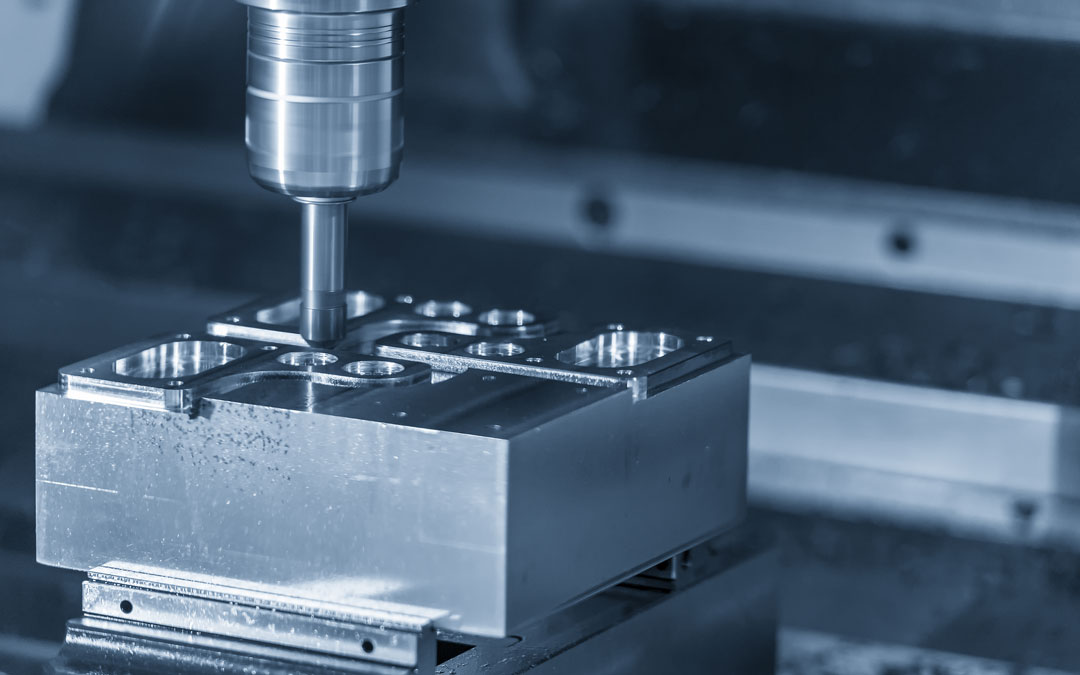

Check out our Handy Guide to CNC Lathes

The first misconception we must dispel is the belief that robots and other automated solutions come on a machine shop floor at the expense of human workers. This is an understandable and common belief (it’s even a trope in fiction), but ultimately one that is incorrect. In fact, robotics help keep jobs from being offshored. In fact, when automation systems are not in place, North American companies simply cannot compete, and jobs are sent overseas. The presence of robots on the shop floor also means human workers don’t need to perform repetitive, boring, or dangerous tasks because these are left to the automated systems.

Manufacturing robots are most commonly used for repetitive jobs—particularly those where the speed, accuracy, and durability a robot provides are in demand. While robots are doing their tasks, human workers can focus on efficiency, innovation, and other processes that lead to further growth and success. With automated systems in place, the shop floor enjoys improved worker safety, increased productivity, and profitability.

Here are five reasons manufacturers use robots:

- Robots create efficiency at every step of production: from handling raw materials to product packaging.

- Robots can be programmed to operate through the night for “lights out”, and continuous production.

- Robotic equipment is flexible and customizable for complex functions.

- Automated systems are highly cost-effective for shops of every size.

- In an aggressive landscape, manufacturers need to embrace automation in order to stay competitive.

Collaborative Robots (Cobots) allow humans and robots to work together in the same workspace.

One type of robot that’s making a greater impact on manufacturing is known as collaborative robots—or cobots. While most automated systems operate independently from human machinists, cobots are designed to work alongside humans in a shared workspace. They are also designed to supplement a human worker—aiding their work on the shop floor, and allowing them to achieve higher levels of productivity.

Robotics represents a revolution in manufacturing—they are considered a key component of industry 4.0 for a reason! Robots and other automated systems move quickly and accurately and they handle parts too small for human fingers with ease. They also always perform what they’re programmed to do unerringly, which is why many designers will plan for parts to be made by robots from the outset.

With technology advancing on an almost daily basis, reducing the need for fixturing and tooling, robots are at the center of a more productive manufacturing world, which is why every manufacturer needs to know the undeniable benefits automated systems bring to the shop floor. This is why the innovators at Winn Machine turn to robots and automated systems to pull a little more efficiency out of our shop, which allows us to serve our customers a little better every day.