Here at Winn Machine, we love to talk about machining, milling, turning, and cutting. It’s what we do, and we are proud of what we do. But today we want to talk about another important topic to anyone in the metalworking industry, metal identification techniques.

Metal selection and identification are important throughout a part’s production process from manufacturing engineers who select the metal that meets the requirements of the finished part to fabricators and machinists who need to identify that they are working with the correct material. The result of selecting the wrong metal at any step of the process can result in defective parts or broken machines.

So how do engineers and metalworkers identify different metals? Here are a few tried and true, traditional methods used today in metal identification.

Find out How to Implement a VMI Strategy

The Appearance Test

The most basic test is done by observing the metal’s appearance. Though not always as accurate as most tests a trained/experienced metal worker can identify metals by characteristics such as the color and texture of their machined and unmachined surfaces.

The Fracture Test

Similar to the appearance test the fracture test is done by visual observation. However, with the fracture test the appearance of a broken piece of the metal is what is observed. This test is performed by notching the metal, then breaking off a piece of it. From this, the metal can be identified by examining the surface of the break or by additionally studying the chips with a hammer and chisel.

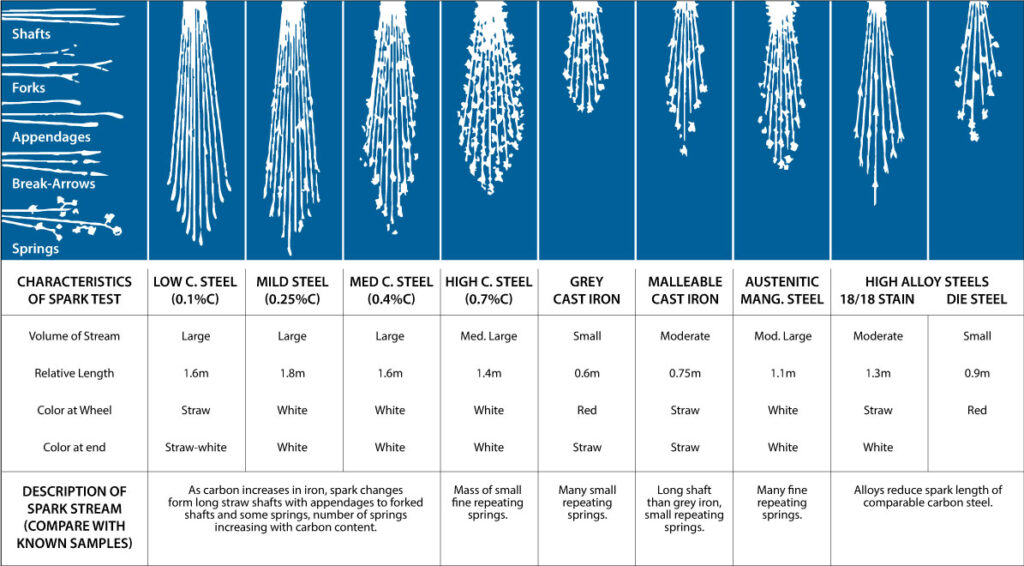

The Spark Test

A spark test is performed by placing a sample of the metal against a grinding wheel hard enough for it to emit a stream of sparks. The stream of sparks is then observed and evaluated by the color, shape and number of the sparks, and length of the spark stream. With this information, the metal type can easily be determined using one’s knowledge or a chart (see below).

Spark Test Charts are used to compare the results of a metal’s spark characteristics to metal types.

The Rockwell Test

This test is to determine the type of metal based on its hardness or softness. For this test, you will need a Rockwell Hardness-Testing Machine. In this test, a cone-shaped object or ball indenter is pressed into the metal with a determined minor and major force. The depth of the indent created is then measured to determine the hardness of the metal and used to identify the metal type.

Brinell Hardness Test

Like the Rockwell Test, the Brinell Hardness Test is used to identify a type of metal based on its hardness or softness. In this test, an indenter is forced into a sample of metal with a load of 3000 kg. However, rather than measuring the depth of the impression as in the Rockwell test, the width of the indent is measured in the Brinell Hardness test to identify the hardness of the metal. This measurement can then be used to identify the hardness and type of metal.

These are traditional methods that have been used to identify metal types since the mechanical revolution and are still used today because of their dependability. With the rise in new technologies have come more modern metal testing types, but these are the ones that have stood the test of time to still be used and relied upon by engineers and metalworkers today.