When it comes to precision machining, tight tolerances and dimensional accuracy are the cornerstones of reliable, high-performance parts.

At Winndeavor, we blend cutting-edge technology, skilled craftsmanship, and stringent quality control to deliver unmatched precision for our clients. Whether it’s aerospace, medical devices, or construction equipment parts, understanding what tight tolerances and dimensional accuracy mean, and why they matter, is key to appreciating the value we bring.

Understanding Tight Tolerances and Dimensional Accuracy

What Are Tight Tolerances?

In manufacturing, tolerance refers to the limits of variation in a part’s physical dimensions.

In other words, it’s a range within which a part can vary while still being fit for use in the larger system. A tight tolerance means that the allowable variation is very small, demanding greater control and precision.

For example, the aerospace industry often requires tolerances as tight as ±0.0005 inches, while construction equipment parts may typically allow ±0.005 inches. These ranges depend on the final use of the component.

What is Dimensional Accuracy?

Dimensional accuracy measures how close a manufactured part is to its specified dimensions. This is different from precision, which is about repeatability or consistency across multiple parts. A factory may consistently produce parts close that are all similar (which is technically precision), but miss the mark of the target dimension (poor accuracy).

Maintaining dimensional accuracy ensures parts fit and function correctly, especially when assembling complex systems.

Why Tight Tolerances and Accuracy Matter

Strict tolerance control affects:

- Performance: Parts that don’t fit correctly can cause wear, noise, or failure.

- Safety: Tolerance errors can lead to malfunction, potentially dangerous in sectors like medical devices or aerospace.

- Product Lifecycle: Precise components last longer and reduce maintenance.

- Cost: Poor tolerance control increases scrap, rework, and downtime. These all impact project budgets and timelines.

Challenges in Achieving Tolerances

Achieving these precise goals is not easy. Several factors complicate the process:

- Material Variability: Differences in raw material properties can affect machining results.

- Machine Wear & Environment: Over time, machines lose calibration, and temperature/humidity changes can cause expansion or contraction.

- Tool and Fixture Rigidity: Insufficient rigidity leads to deflection during cutting, reducing accuracy.

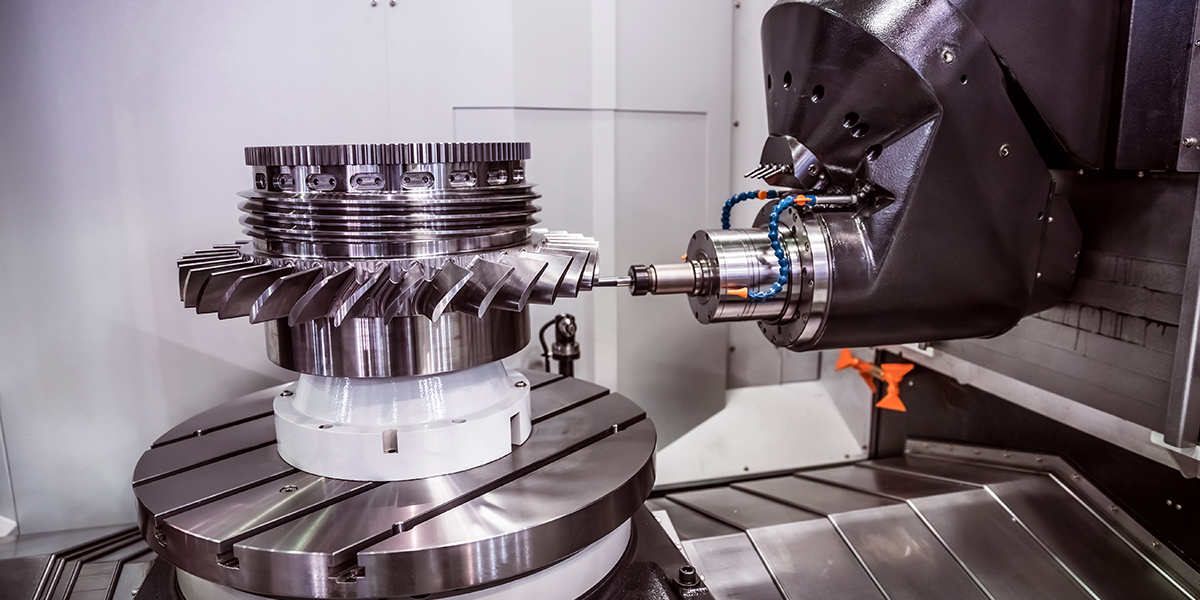

- Complex Geometries: Small features and intricate shapes are inherently harder to machine precisely.

- Human and Measurement Limitations: Operator skill and the precision of measuring tools also place limits on achievable tolerances.

Winndeavor’s Precision Process

At Winndeavor, we rise to these challenges with a comprehensive approach:

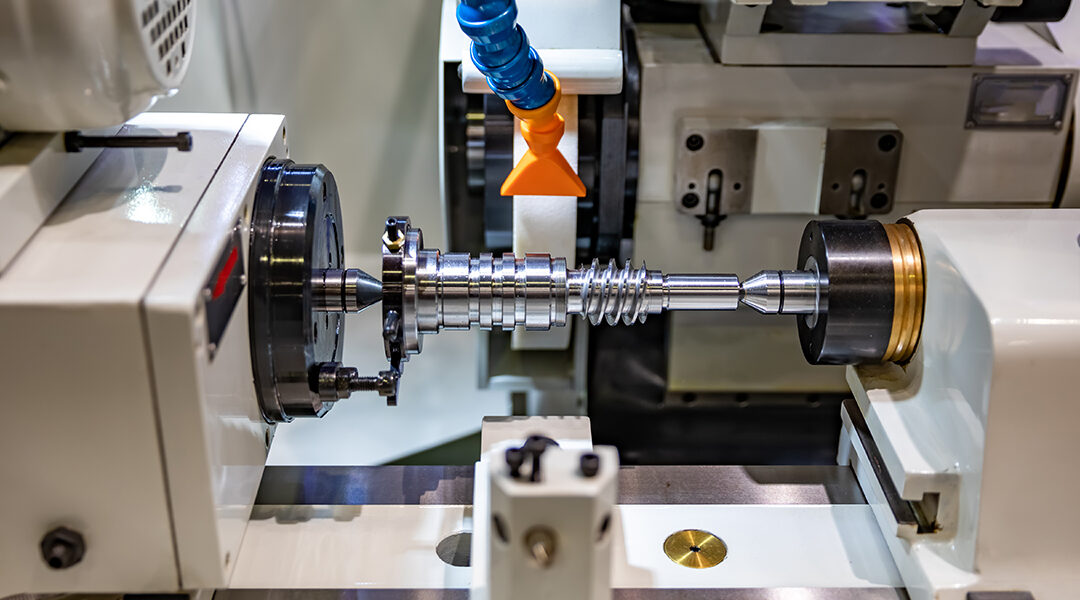

1. Advanced Machinery and Technology

We utilize CNC machining centers equipped with the latest control systems and fine-tuned tooling. Automation and robotics reduce human error, ensuring consistency and precision beyond manual capabilities.

2. Skilled Workforce and Continuous Training

Our machinists and engineers bring extensive expertise in interpreting blueprints and specifications. Ongoing training helps them stay ahead of new techniques and industry standards.

3. Strong Quality Control Process

Our inspection arsenal includes coordinate measuring machines (CMMs), laser scanners, and micrometers. We conduct in-process inspections and real-time data analysis, followed by thorough final inspections to ensure every part meets the strictest tolerances.

4. Material Selection and Preparation

We source high-grade raw materials and apply meticulous pre-machining treatments to guarantee stability and consistency throughout the process.

5. Collaborative Engineering and Design Support

Working closely with clients during the design phase, we provide feedback on manufacturability and integrate Design for Manufacturability (DFM) principles to make sure tight tolerances are achievable without unnecessary cost or complexity.

Benefits of Choosing Winndeavor for Precision Manufacturing

When you partner with Winndeavor, you gain:

- Reduced risk of part failure and field returns

- Improved assembly fit for enhanced final product performance

- Cost savings from minimized scrap and rework

- Faster project turnaround through streamlined manufacturing

- Trusted, long-term partnerships based on consistent quality

Partner with Precision

Ready to bring your tight tolerance requirements to life? Winndeavor offers CNC machining, CAD/CAM support, and expert engineering consultations tailored for tolerance-critical parts. Visit our website to contact our team to discuss your project’s unique needs.