When it comes to manufacturing, accuracy and precision are paramount. As a purchasing manager, you understand the challenges of procuring high-quality, regulation-compliant parts while also aiming to optimize time and cost efficiencies. One solution that can address these challenges is the utilization of coordinate measuring machines, or CMM. What is a coordinate measuring machine? What are the benefits they offer? And why are they a centerpiece to every great machine shop? Find out as we discuss the significant difference these machines can make in your procurement process.

Check out our Guide to CNC Lathes

What is a Coordinate Measuring Machine?

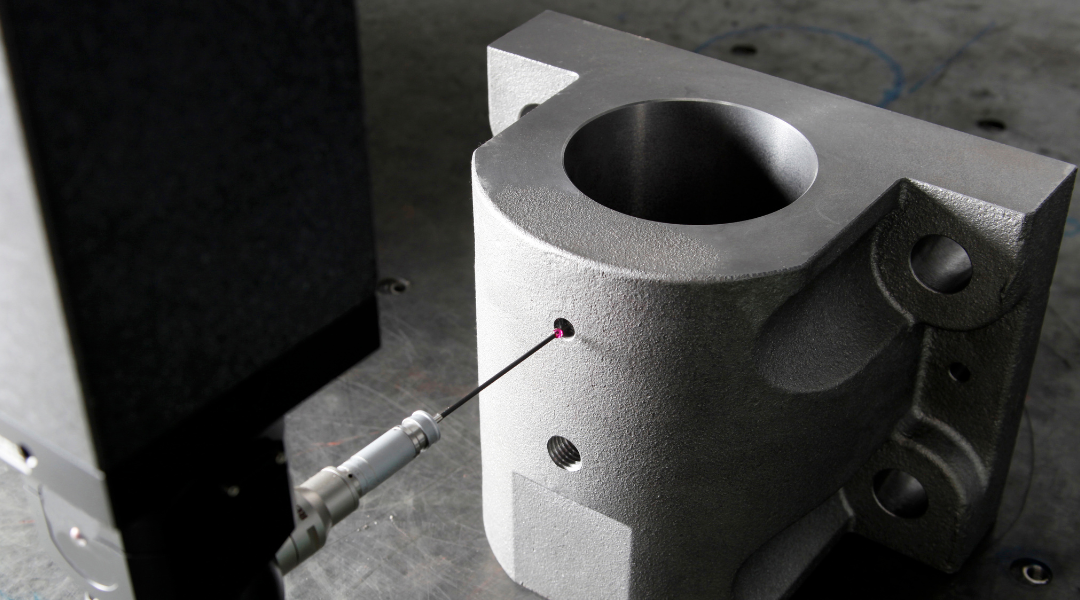

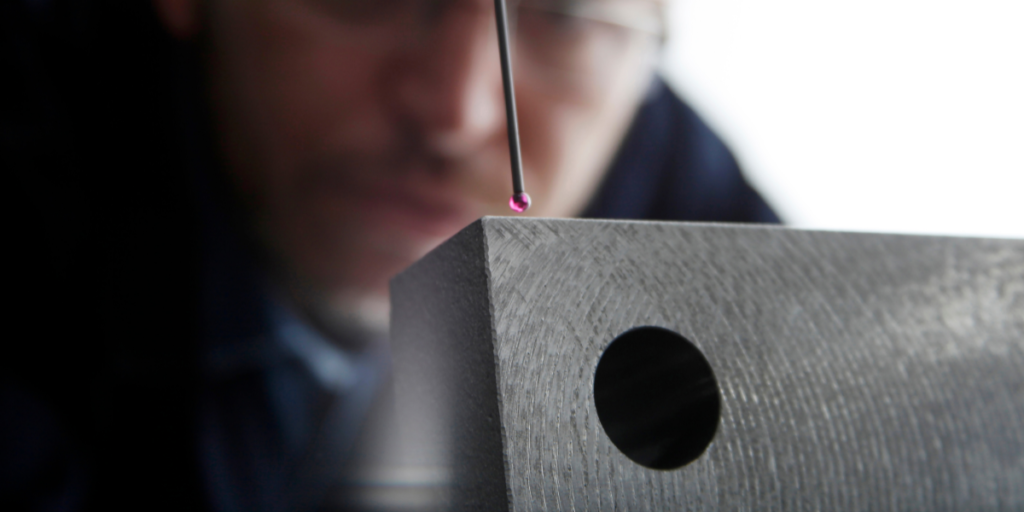

A Coordinate Measuring Machine (CMM) is an advanced measurement system used to assess the geometric characteristics and dimensional accuracy of manufactured parts. Combining software, sensors, and precision probes, CMMs capture detailed data points and measurements in three-dimensional space, ensuring the utmost accuracy in quality control. This technology has revolutionized the way manufacturers evaluate the conformity and precision of their products, ultimately reducing defects and enhancing overall product quality.

The Benefits of Coordinated Measuring Machines

Have you ever gotten a part—or an entire shipment of parts—that was just wrong enough that it was unusable? It’s a frustrating situation because it means your entire supply chain process comes to a screeching halt. Along with wasting time, starting over means dipping into your budget again after you’ve just wasted money on components that are completely useless.

That’s where CMM comes in. CMMs are a proactive measure used by top-quality shops to catch QC issues before the part gets shipped. What does this mean for you? A couple of things.

Reliable and Precise Measurements

CMMs provide highly accurate measurements, often within microns, allowing for the detection of even the smallest deviations from design specifications. Through tactile or optical probing systems, CMMs ensure every point, contour, and surface is scrutinized, resulting in a comprehensive assessment of the part’s conformity. What does this mean for you? As the machine shop partner, you’ll be able to rest assured knowing even the tightest of tolerances have been verified.

Increased Efficiency and Productivity

By automating the measurement process, CMMs reduce the time required for inspection compared to manual methods. These machines generate detailed reports and provide real-time feedback on the quality of manufactured parts. As a result, CMMs contribute to faster inspection cycles, faster development times, and improved overall efficiency in the production process. Say hello to reduced lead times and faster delivery of high-quality parts!

Coordinate measuring machines are invaluable because they speed up the inspection process and boost productivity.

Reduction of Human Error and Variability

Human error is inherent in manual inspection processes, leading to inconsistent results and potential defects. CMMs eliminate this variability by performing precise measurements with enhanced accuracy and repeatability. With reduced reliance on human intervention, manufacturers minimize the risk of errors and ensure consistent quality throughout the production cycle.

Cost-Saving Potential through Optimized Quality Control

Implementing a CMM into the manufacturing process helps identify potential defects early on, reducing scrap rates and rework costs. CMMs catch issues before they become more problematic downstream, saving both time and money by minimizing material, labor, and delivery waste—optimizing overall quality control. Thus, partnering with a machine shop that uses CMM means you can optimize your budget.

Trust a Partner that Utilizes CMM. Trust Winndeavor.

When it comes to precision machining needs and utilizing coordinate measuring machines, Winndeavor is your trusted partner. With a proven track record in the industry, Winndeavor has extensive experience in delivering high-quality machining solutions that meet and exceed the most demanding standards. We leverage our advanced machinery and skilled employees to consistently deliver superior outcomes across various industries, including aerospace, defense, industrial, medical, and commercial.

If you’re ready to optimize your results when working with a machining partner, look no further than Winndeavor. Reach out today and experience the advantages of working with a reputable machine shop that prioritizes customer satisfaction and delivers exceptional results every single time.