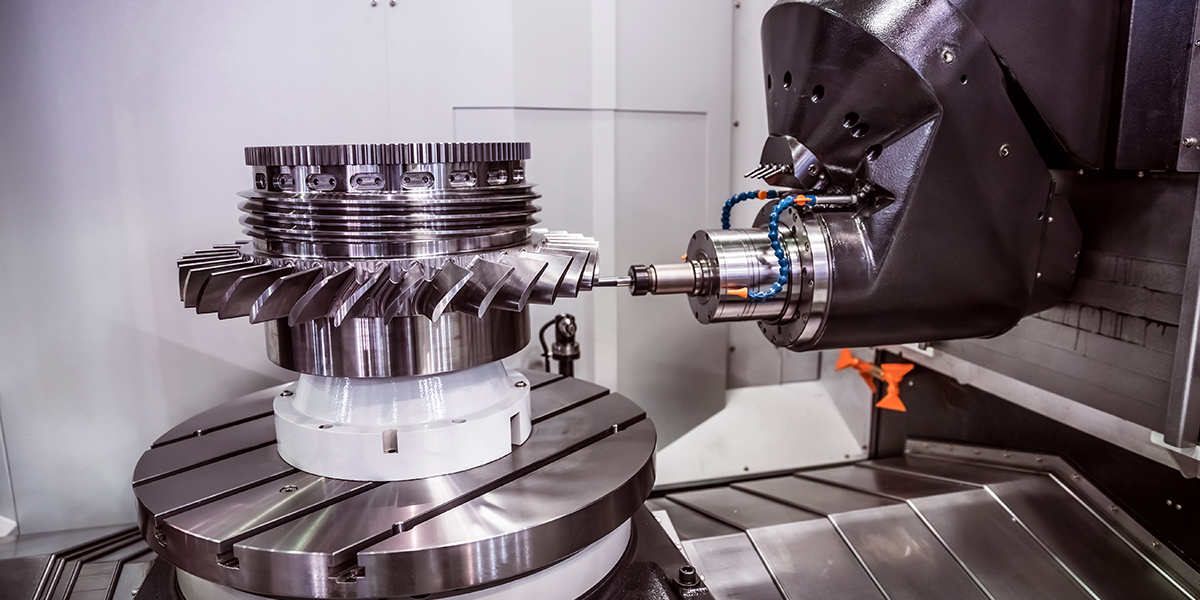

Computer Numerical Control (CNC) technology has revolutionized manufacturing, turning complex designs into precise products with minimal human error. At the heart of CNC machining are programming languages—specialized codes that direct machines on how to create detailed parts and tools. For anyone involved in manufacturing, engineering, or design, understanding CNC programming languages is vital. This article will introduce you to the basics of CNC programming languages, explore their types, and highlight their importance in today’s industry.

What Are CNC Programming Languages?

CNC programming languages are sets of instructions written in computer code that tell CNC machines how to move, cut, drill, or shape materials. Unlike conventional machining that relies heavily on manual control, CNC programming automates these tasks with precision and repeatability.

These languages essentially translate an engineer’s print into a language the machine understands. This way, manufacturers can produce complex parts consistently, optimize production speed, and reduce waste.

1. G-Code

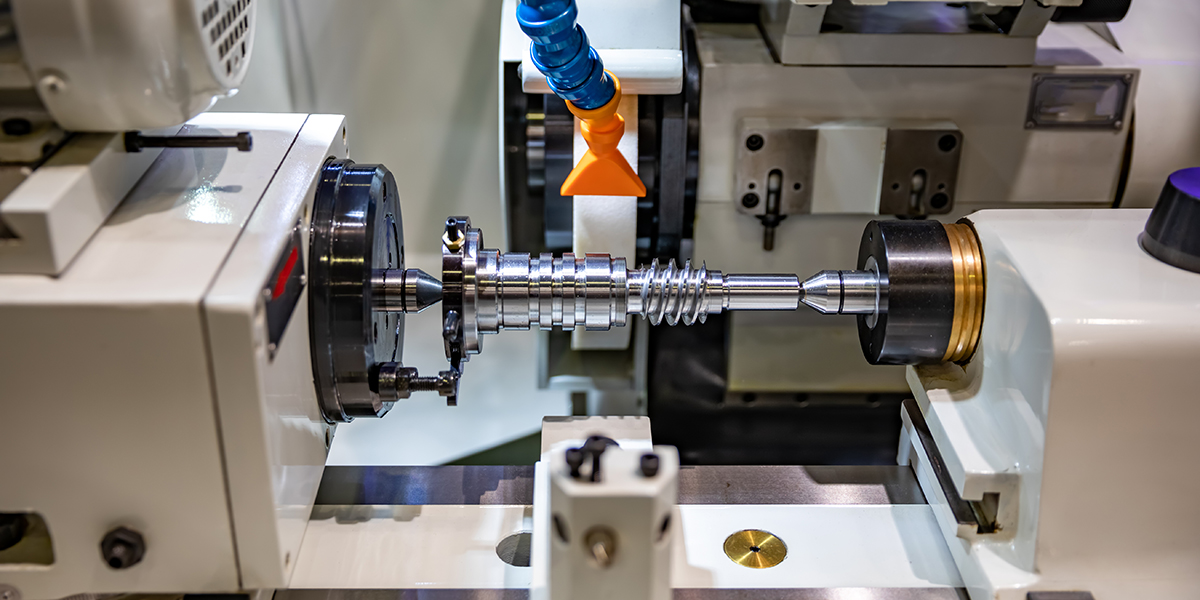

G-Code is the most widely used CNC programming language worldwide. Originating in the 1950s, it has become the industry standard for programming CNC milling machines, lathes, and routers.

How it works

G-Code comprises commands starting with the letter “G” followed by numbers (e.g., G01 for linear movement). These commands instruct the machine where to move the cutting tool, how fast to go, and the type of operation to perform.

Example

A G-Code command like G01 X10 Y20 F150 tells the machine to move the cutting tool to position X=10, Y=20 at a feed rate of 150 millimeters per minute.

Why it’s important

G-Code’s simplicity and versatility make it ideal for a wide range of applications, from simple cuts to multi-axis machining.

2. M-Code

While G-Code focuses on motion, M-Code controls the machine’s auxiliary functions, such as starting or stopping the spindle, turning on coolant, or changing tools.

Example

M03 starts the spindle clockwise, and M05 stops it.

Integration

M-Codes work alongside G-Codes to coordinate movement and machine functions seamlessly.

3. Parametric Programming

This language allows programmers to write CNC code with variables and conditional statements, making it possible to create flexible and reusable programs.

Benefits

It reduces programming time for parts with repetitive features and enables easier adjustments when design specifications change.

Use case

Ideal for batch production where slight modifications to parts occur frequently.

4. Conversational Programming

Many of tody’s CNC machines feature conversational programming, which uses a more user-friendly interface rather than direct code writing.

Advantage

Operators enter parameters like dimensions and tool paths via a dialogue box instead of writing lines of code.

When to use

Ideal for programming at the machine or quick prototyping, though less flexible for complex tasks than G-Code.

Why Understanding CNC Programming Languages Matters

Mastering CNC programming languages benefits businesses and individuals by:

- Enhancing Precision: Automated, coded instructions eliminate human errors, ensuring consistent part quality.

- Increasing Efficiency: Programs can be reused or modified quickly, speeding up production cycles.

- Fostering Innovation: Skilled programming allows complex designs and high-precision machining that manual methods cannot achieve.

- Reducing Costs: Minimizing material waste and machine downtime leads to cost savings.

For businesses exploring CNC machining solutions, partnering with experienced professionals like those at Winndeavor can make all the difference. We offer expert CNC programming services that optimize manufacturing workflows while achieving the highest quality standards.

Improving Your CNC Knowledge with Winndeavor

Ready to take your manufacturing capabilities to the next level? Winndeavor provides comprehensive resources to help you learn and apply CNC programming languages effectively. From tutorials to custom programming services, we support your journey in mastering this critical technology.

Explore our CNC programming services and get expert guidance tailored to your specific manufacturing needs.

Conclusion

CNC programming languages are the backbone of modern manufacturing, translating innovative designs into precise, consistent products. Whether working with G-Code, M-Code, parametric scripts, or conversational programming, understanding these languages empowers businesses to innovate and compete in today’s demanding market.

At Winndeavor, we’re committed to helping you unlock the full potential of CNC technology. Visit our website to discover how our CNC expertise can transform your production capabilities.