Turning centers, natural descendants of the manual lathe, are an essential machine tool used by the manufacturing industry. These versatile machines have played a pivotal role in shaping raw materials into finished products with precision and accuracy. While the general principles of turning centers have remained unchanged over time, significant advancements and innovations have been introduced in the last decade. Let’s explore the evolution of turning centers and highlight the key innovations that have revolutionized their functionality.

Stay Ahead of Supply Chain Issues with Our Helpful Infographic!

History of Turning Centers

Turning centers have a long and fascinating history dating back to ancient civilization. The ancient Egyptians utilizing rudimentary wooden lathes for shaping and sanding materials. A significant leap in efficiency occurred during the Middle Ages with the introduction of pedal-driven lathes. However, it was during the Industrial Revolution that turning centers underwent a transformative phase. Steam power and motor-driven machines replaced manual operation, ushering in increased productivity and innovation in the turning process.

During the 18th and 19th centuries, as the Industrial Revolution gained momentum, the first powered turning centers emerged. The introduction of steam-powered lathes and motor-driven machines marked a pivotal moment, enabling faster and more efficient shaping of materials. This technological advancement laid the groundwork for subsequent innovations and the eventual integration of digital technology in turning centers.

In more recent times, the integration of digital technology through Numerical Control (NC) machines marked a turning point, evolving into the sophisticated Computer Numerical Control (CNC) technology. CNC turning machines, with their computer-controlled precision and efficiency, have become the preferred method for companies seeking accurate and cost-effective production processes to meet the growing demand for complex and precise parts in various industries.

Key Turning Center Advancements and Innovations

The last decade has seen some of the most significant advancements and innovations in the turning center industry, which have revolutionized their functionality and expanded their capabilities. Let’s examine some of them:

Multi-axis Capability

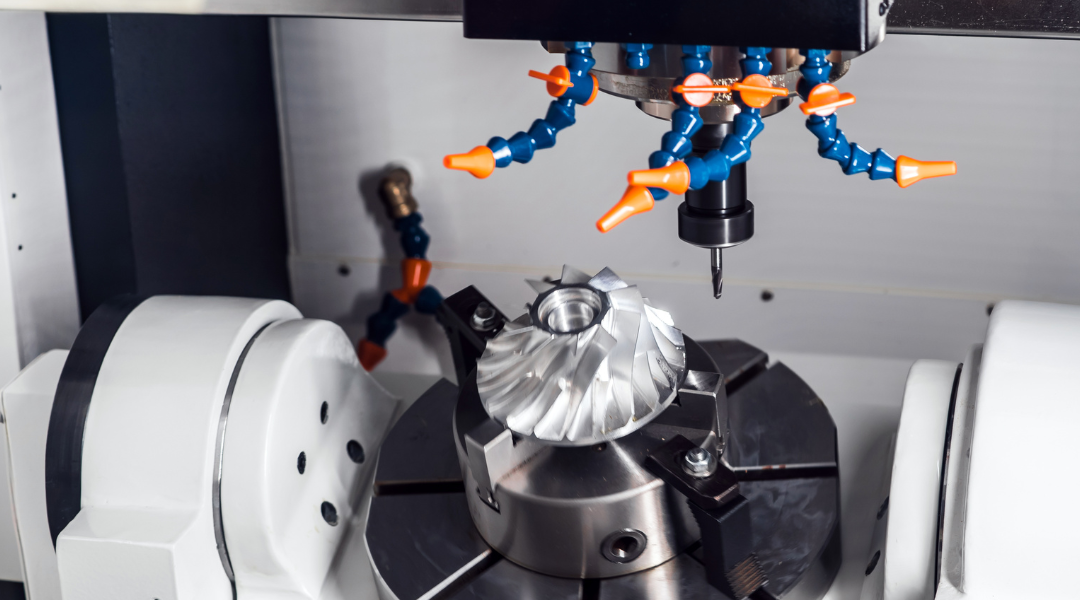

While traditional lathes typically had two axes of movement, modern turning centers are equipped with multiple axes, typically five or more. This allows for greater flexibility and the ability to perform complex machining operations without requiring repositioning of the workpiece.

Integrated Automation

Turning centers now often include integrated automation features, such as robotic loaders and unloaders, that can handle material loading and unloading tasks automatically. This reduces the need for manual intervention and increases productivity.

CNC Technology

Computer Numerical Control (CNC) technology has greatly advanced in recent years, allowing for more precise control and monitoring of turning centers. CNC systems can program and execute complex machining operations with high levels of accuracy and repeatability.

CNC capabilities allow for high precision machining of even the most complex tasks.

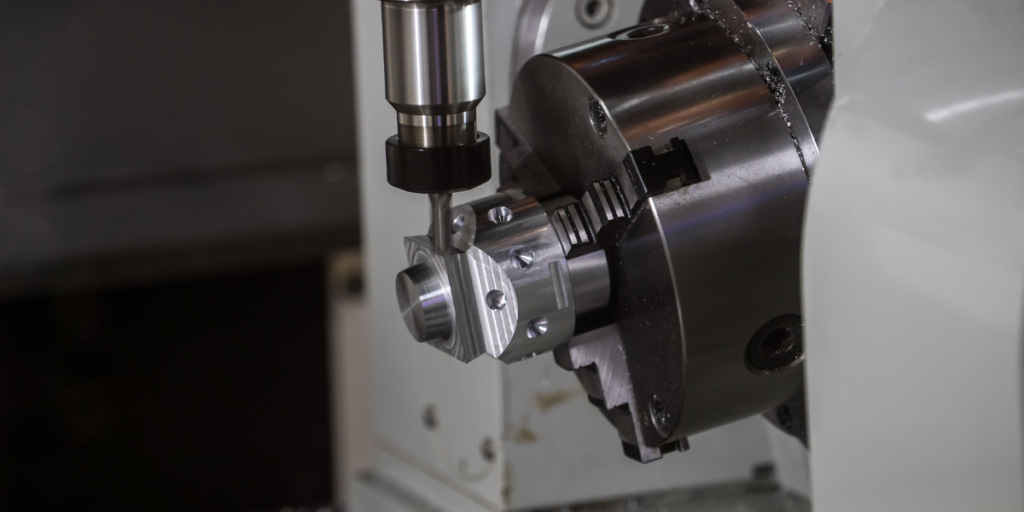

Live Tooling

Many modern turning centers are equipped with live tooling capabilities. This means that in addition to traditional turning operations, the machine can also perform secondary operations such as drilling, milling, and tapping without the need for retooling or transferring the workpiece to another machine.

Advanced Control Systems

These tools now feature advanced control systems that provide operators with intuitive interfaces and real-time monitoring capabilities. This allows for better visualization and control of machining processes, as well as quick adjustments and optimizations as needed.

Improved Cutting Tools and Tool Holders

Innovations in cutting tool technology have resulted in improved tool life, cutting speeds, and surface finishes. Additionally, tool holders have been developed to provide more stability and rigidity, allowing for better machining performance.

Energy Efficiency

Turning centers have become more energy-efficient, with improved design features that reduce power consumption and waste heat. This not only reduces operating costs but also has a positive environmental impact.

Winndeavor’s Commitment to Precision Machining

In the dynamic landscape of the manufacturing industry, the evolution of turning centers stands as a testament to human ingenuity and technological progress. And as we look towards the future, turning centers will undoubtedly continue their journey of refinement and innovation. Winndeavor, with its cutting-edge turning centers and a team of seasoned professionals, stands as a beacon of excellence in precision machining services. Our unwavering commitment to precision, quality, and customer satisfaction positions us as a leader in the industry. The evolution of turning centers is an ongoing narrative, and at Winndeavor, we are dedicated to being at the forefront of shaping its next chapters, delivering exceptional results for all your machining needs.