If you look at the photo above, you may be wondering “who on earth would be excited about a dumpster?” We would! Why? Because this photo represents our commitment to sustainable manufacturing. This is our new recycling dumpster, and it’s going to help us cut the amount of waste that gets sent to the landfill in half.

Find Out How to Implement a VMI Strategy

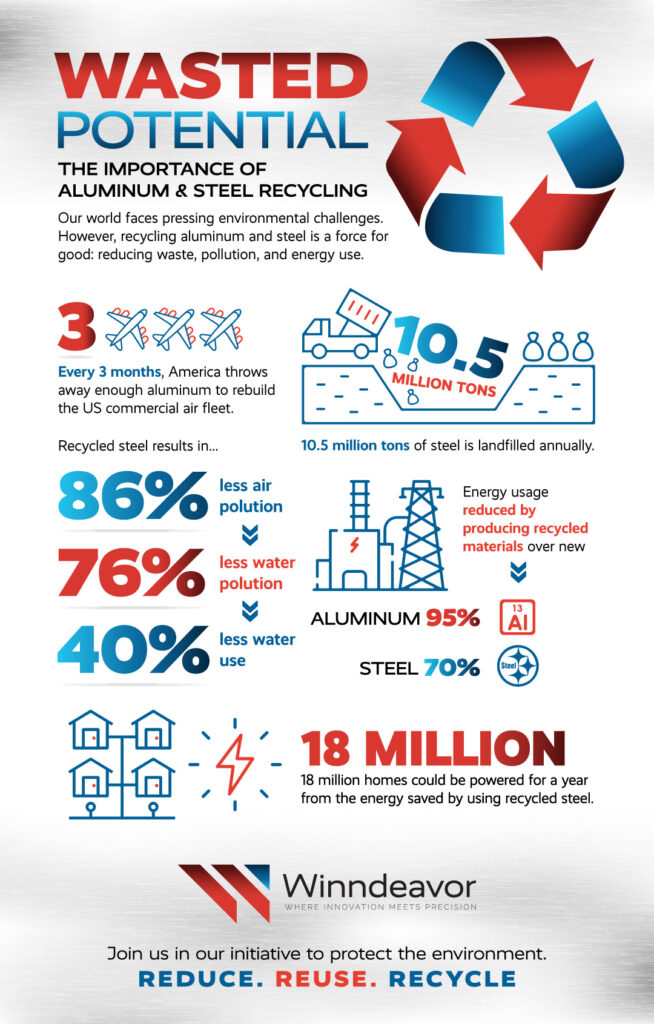

At Winndeavor, sustainable manufacturing is not just a buzzword – it’s a mindset and a responsibility. We understand the importance of minimizing our environmental impact while still delivering high-quality precision components to our clients. That’s why we have implemented sustainable manufacturing solutions throughout our operations.

One of our key initiatives is waste reduction. Our recycling dumpster is just one example of how we are taking steps to minimize waste. By separating recyclable materials such as metals, plastics, and paper, we divert a significant amount of waste from ending up in the landfill. This not only helps to preserve our environment but also reduces the demand for raw materials, ultimately leading to a more sustainable manufacturing process.

The Importance of Sustainable Manufacturing

Sustainable manufacturing is of utmost importance in today’s world due to its significant benefits for both businesses and the environment. Here are some key reasons why sustainable manufacturing should be a priority:

Environmental Impact

Traditional manufacturing processes often result in high levels of waste generation, energy consumption, and pollution. Sustainable manufacturing practices focus on minimizing these negative environmental impacts. By reducing waste sent to landfills, conserving energy, and minimizing pollution, sustainable manufacturing helps protect natural resources, preserve habitats, and mitigate climate change. It helps create a healthier and cleaner environment for all.

Take this with you – Click above to Download!

Cost Savings

Incorporating sustainable practices in manufacturing doesn’t just benefit the environment; it also makes good business sense. Reducing energy consumption optimizes resource usage and minimizes waste generation, allowing companies to significantly cut operational costs. Energy-efficient equipment and processes lead to substantial savings on utility bills, while waste reduction measures reduce landfill disposal and waste management expenses. In addition, implementing sustainable practices helps businesses avoid potential fines and penalties associated with non-compliance with environmental regulations.

Reputation and Brand Image

In an ecologically conscious world, consumers are increasingly demanding environmentally responsible products from businesses. Adopting sustainable manufacturing practices enhances a company’s reputation and brand image as it signals a commitment to ethical and environmentally friendly operations. Consumers are more likely to support and choose products from companies that prioritize sustainability. By demonstrating environmental responsibility, businesses attract a wider customer base and build long-term brand loyalty.

Supply Chain Efficiency

Sustainability is not limited to an individual company’s operations. It extends across the entire supply chain. Collaborating with suppliers and partners who share a commitment to sustainable practices streamlines operations, promotes responsible sourcing, and ensures the social and environmental responsibility of the entire production process. By working together, businesses create a more efficient, transparent, and sustainable supply chain, benefiting all stakeholders involved.

Sustainable Manufacturing Starts at Winndeavor

Sustainable manufacturing is not just a priority for Winndeavor. It’s ingrained in everything we do. Partnering with us means you can benefit from high-quality precision components and contribute to a greener and more sustainable future. Contact us today to learn more about how we can help your business achieve its sustainability goals while delivering exceptional products. Together, let’s shape a better tomorrow.