Every machinist in the manufacturing industry has probably heard about CNC Swiss turning. Swiss turning has become one of the most popular and fastest-growing types of machining in recent years. This growth in popularity can be attributed to Swiss turning’s ability to produce extremely small parts quickly and with great accuracy. Here are a few more things to know about CNC Swiss turning machines if your parts require the fine precision that Swiss turning offers.

Check out our Guide to CNC Lathes

How Does CNC Swiss Turning Work?

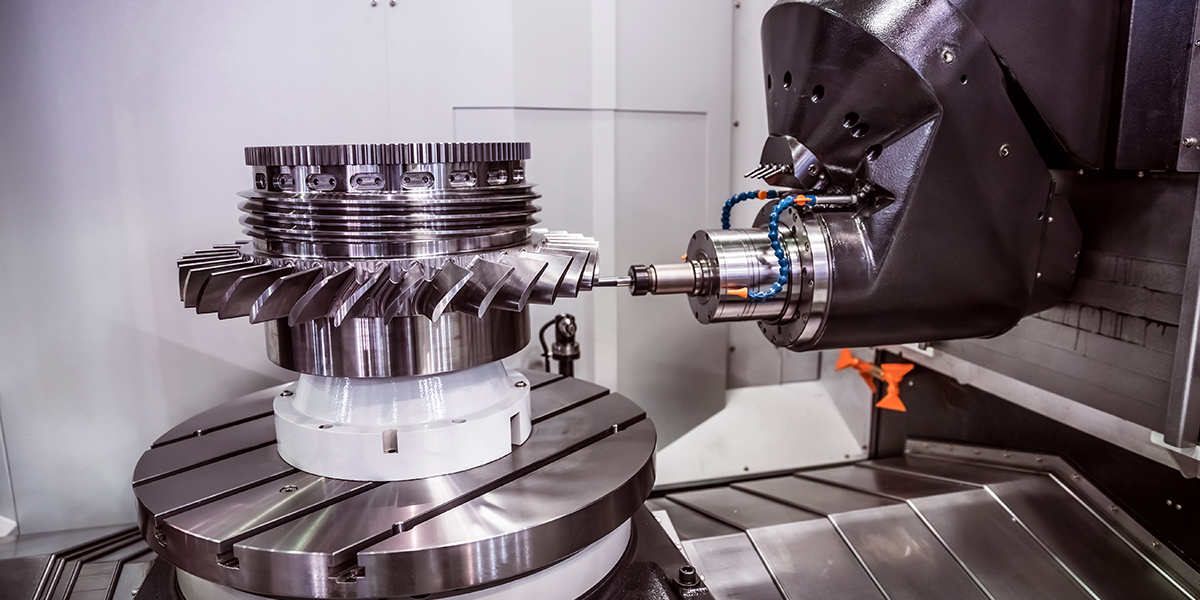

CNC Swiss machine uses a bar stock that spins and slides through a guide bushing. This provides a powerful point of support, regardless of the length of the material in use. Turning tools are mounted to the face of the guide bushing and cut the stock near the bushing. Gang slides carry holders for various types of tooling and can also support live tooling. Many Swiss machines feature sub-spindle and back-working tool stations, dramatically increasing the functionality and throughput capability of the machine.

Benefits of Swiss Turning

There are many benefits to CNC Swiss turning. Here are just a few important ones to know:

- Fast-Paced

- These machines can produce parts at a faster rate than other styles of CNC machines. Depending on the material, part size, and complexity, Swiss turning machines can outproduce a conventional CNC by a significant amount.

- Ability to Create Complex, Delicate, and Small Parts

- Thanks to how well the bar stock is supported, Swiss turning can produce more complex parts with thinner walls, delicate features, and deeper cuts than other CNC machines.

- Creates Ready-To-Ship Parts

- Swiss machines produce parts that do not require additional operations or refinements, making them able to be shipped out quickly.

- Precision

- Precision is key to properly producing any part—Swiss turning has one of the highest precision rates in the industry.

Utilizing CNC Swiss turning is a great way for any machine shop to create small and complex parts at a lower cost than other CNC operations. Now that you know how Swiss turning works and what the benefits are, you can consider turning to a shop equipped with Swiss turning machines. If you have additional questions about CNC Swiss turning, contact our team at Winn Machine today!