In the past, VMCs generally favored precision while horizontal machining centers (HMCs) generally favored production—but times have changed. By automating your VMC with a pallet changer, you can still deliver precision while enabling continuous, uninterrupted production.

Check out our Six-Step Guide to Setting up Vendor-Managed Inventory!

Changing the Game

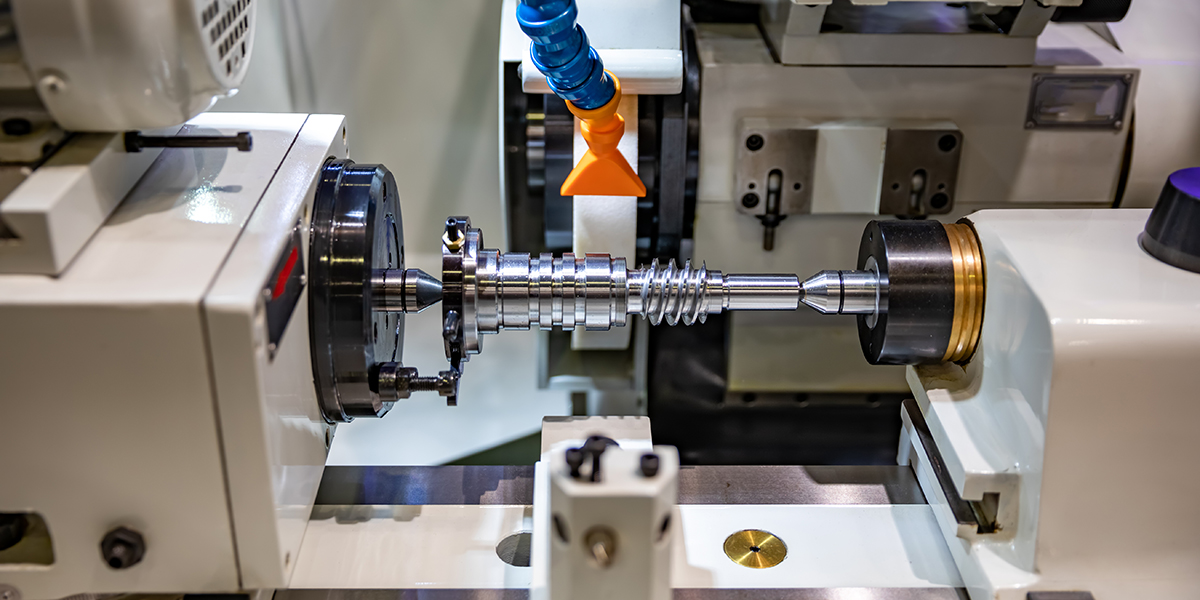

Automatic pallet changers allow CNC machine operators to load and unload workpieces in one area of the tool, while the VMC is busy making chips and parts in another. These turntable-style pallets are automatically moved in and out of the machine with a simple push of a button.

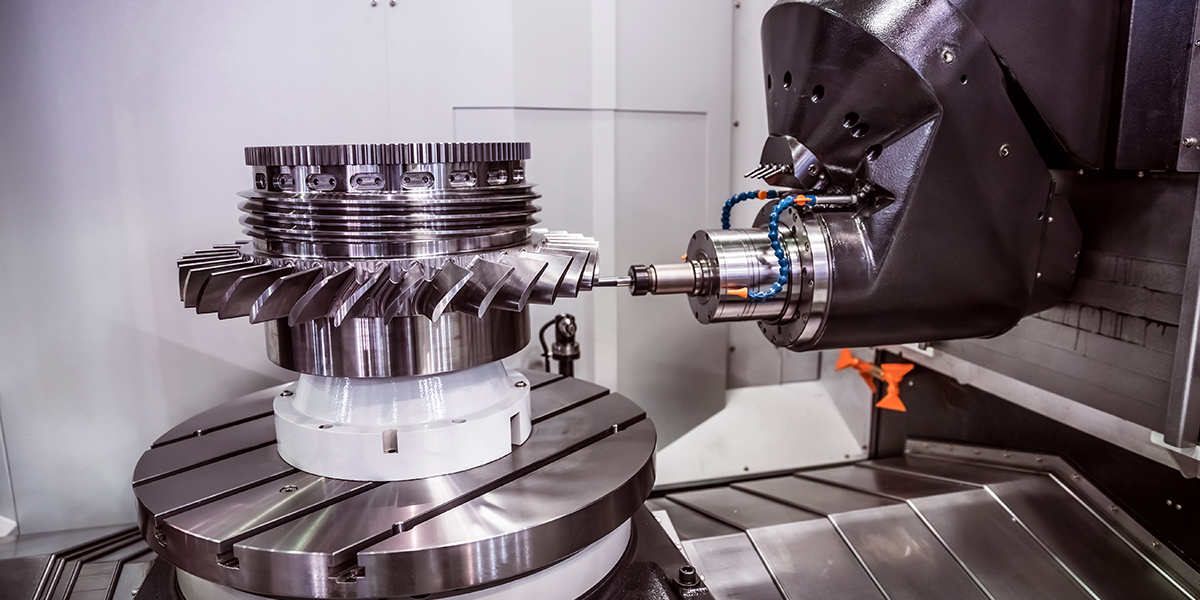

The increases in spindle utilization and operator productivity for these types of machines are dramatic and impactful. By allowing operators to load, unload and inspect parts on one pallet while the machine continues to work without interruption on parts fixtured on the other pallet, machine shops can reduce costs and increase flexibility—without increasing the size of their workforce or shop floor. This in turn, benefits customers, as the machine shop can provide larger volumes of parts at more competitive pricing—without sacrificing quality.

A part is loaded by a CNC machine operator in one area of the tool while the VMC is working on a part in another area. When ready the turntable-style pallets are automatically moved, switching the parts.

Lightning-Fast Lead Times

Every shop has received a call from panicked buyer, pleading for delivery the next day or even the same afternoon. With the addition of extra fixturing, shops can use their VMC / pallet changer system to setup and run multiple jobs on a single machine to meet these types of demands. For example, on a VMC with an automatic pallet changer, an operator could run a small job of, say, one hundred pieces right next to a big production job of thousands of pieces on the same pallet. This can enable workers to complete work in a single shift, eliminating the need to run additional shifts just for a specific order.

If you’re searching for a machine shop that can provide high-precision parts, quickly and for a good price, take a look at their equipment list or just ask them if they automate their VMCs with pallet changers. If you get a positive response, chances are they can deliver exactly what you’re looking for.